ajames54

Guest

So I'm looking for an underwater flash to use with my digital Camera, and for a ballpark price of 650 USD I can get a fully automatic strobe with a guide number in air of something around 20. Which for a surface flash should retail at around 45$

What I am used to is flashes with guide numbers between 120 and 600 working the theory that it is always possible to cut down light output but if it aint there then it aint there.

So what I figure is this..

I have a spare Vivitar 285 (GN 120) these are available on ebay for about $50.

I think I'll go with the Vivitar because while I have other spare flash units I've found the thyristor unit (the light sensor that makes the flash "automatic") is the most consitantly accurate I've found without using TTL.

A company called WEIN makes a digital slave which will ignore the preflash from the camera. Price for that is around $75..

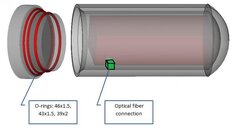

My initial thought was to build the Case from ABS pipe because it is quite stiff and can be heated and re-shaped to a limited extent.. cheap and easy .. however it is black and opaque (OK the flash would be behind a Polycarbonate lens). There would be some issues to resolve around triggering the flash and getting light to the thyristor.. I'm sure I can get around them using Fiber-Optic cable but that adds a PITA factor I don't want to deal with if I don't have to.

So what was my point in all this you ask?

I'm looking for info on either forming Polycarbonate or Lexan sheets or making formed fiberglass stiff and strong enough to handle the preasures.. anyone with info on how to water proof switches would be well thanked .. access is not necessary but would really be nice to have..

If I get it to work I'll end up with a flash that will throw around 35 times as much light as the $650 dollar option .. and 5 to 20 times as much as options costing in the multiple thousands..

What I am used to is flashes with guide numbers between 120 and 600 working the theory that it is always possible to cut down light output but if it aint there then it aint there.

So what I figure is this..

I have a spare Vivitar 285 (GN 120) these are available on ebay for about $50.

I think I'll go with the Vivitar because while I have other spare flash units I've found the thyristor unit (the light sensor that makes the flash "automatic") is the most consitantly accurate I've found without using TTL.

A company called WEIN makes a digital slave which will ignore the preflash from the camera. Price for that is around $75..

My initial thought was to build the Case from ABS pipe because it is quite stiff and can be heated and re-shaped to a limited extent.. cheap and easy .. however it is black and opaque (OK the flash would be behind a Polycarbonate lens). There would be some issues to resolve around triggering the flash and getting light to the thyristor.. I'm sure I can get around them using Fiber-Optic cable but that adds a PITA factor I don't want to deal with if I don't have to.

So what was my point in all this you ask?

I'm looking for info on either forming Polycarbonate or Lexan sheets or making formed fiberglass stiff and strong enough to handle the preasures.. anyone with info on how to water proof switches would be well thanked .. access is not necessary but would really be nice to have..

If I get it to work I'll end up with a flash that will throw around 35 times as much light as the $650 dollar option .. and 5 to 20 times as much as options costing in the multiple thousands..