John on what premise did you determine they were bad tanks? Not trying to pick on you but from what I read they can be hydro tested vip etc. So I don't see a technical base's vs personal opinion.

Sent from my SCH-I545 using Tapatalk

imjustdave, and others wondering,

These were "illegal" cylinders on the civilian market. They were developed under contract for the U.S. Navy, so that the Navy could have anti-magnetic cylinders. There was no ICC (Interstate Commerce Commission) stamp on these cylinders. This means they are not approved for interstate commerce. At that time, there was no testing protocol for cylinders made of aluminum, as all commercially available cylinders were of steel. There is a reason that the person cited above as testing these cylinders did not put his initials as a stamp on the cylinders--he could loose his job/certifiation with DOT if he did. Yes, they may pass the hydro test, but that does not guarantee that they are safe cylinders. The plug has a limited life, and the U.S. Navy had a limited lifetime for these cylinders. They were never built to be hydrostatically tested. Somewhere in my files I have documentation of all this. But can you imagine the liability if a school district allowed an instructor/teacher to have these cylinders for diving, and an accident occurred on these war surplus cylinders (Vietnam War and Cold War)?

As a user of these cylinders in the form of twin 90s, we students learned to hate them, as they were heavy and bulky. Imagine having to do pushups while wearing them--they were instruments of torture for us students at the Underwater Swimmers School. The Navy divers did not like them either, and I know of them being traded for our PJ tanks (twin 42s--steel converted life raft bottles) so the Navy divers would have something light and easily transported via small boat.

SeaRat

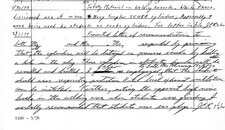

PS, I just found my file, and will add scans of the letters I sent out, along with the entry I made for the school district.

John C. Ratliff, CSP, CIH, MSPH*

*I usually do not use my professional designations here, but in this case because it involved an on-the-job matter and was a professional matter, I am including them. CSP stands for Certified Safety Professional, and CIH stands for Certified Industrial Hygienist. MSPH is Master of Science in Public Health, from Tulane University.