The Chairman

Chairman of the Board

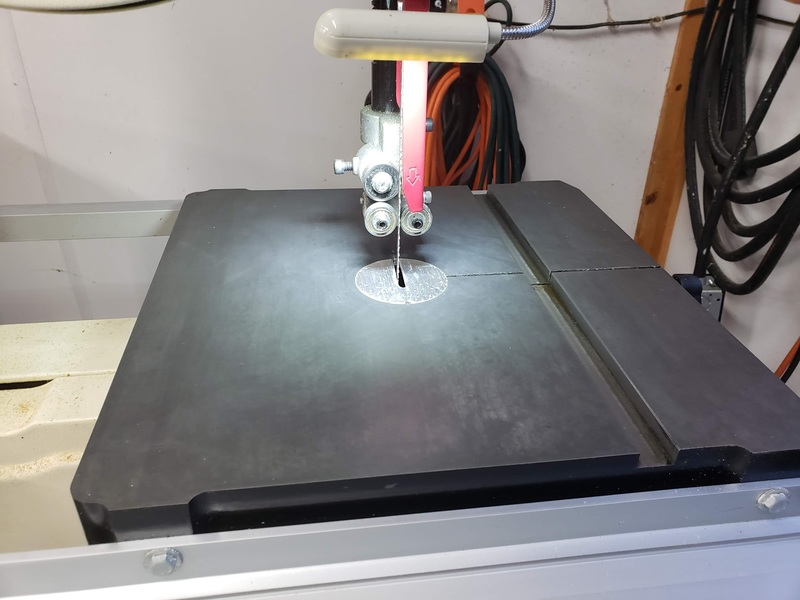

While I was poking around in the shop today, putting things away from ALL THE BOXES, I decided that I really had to spend some time and really set up the Shop Fox bandsaw. I had tried to adjust it earlier and in the end, it howled like a banshee so I knew I had over-tightened something. It actually cuts pretty well as is, but that howl is horrendous. It's time to set it right, so I watched a video three times last night on what to do and how to do it. It took him like ten minutes to set up his bandsaw, but it must have taken me three hours! In the end, it was worth it. I had to take the blade and table off, but she's quiet again and cuts rather well. I also cleaned up it's table and applied two coats of that micro-crystalline wax. I took a 2x4 and cut the into the face the width of the blade. I flipped it around to the back and the blade slid right in without nary a touch. She's true! She's quiet! She's sharp! I had installed a small LED light to really illuminate the work and she looks awesome: