The Chairman

Chairman of the Board

OK, I got to print my project today. No, not the one I posted earlier. It was created using "front" as the plane on which I worked and extruded. When I went to print, it was on its side, facing me. I tried to figure out how to flip it, but alas I could not suss that out. Since I had my tablet with me, I thought I would see how fast I could whip it up. It took me right at 20 minutes to accomplish what took me hours the day before. It was magical and it even looked better. I changed the extrusion from 25mm to 50mm thick. that might be overkill. It was a 4:48 print. I wasn't willing to wait that long, so I went back tonight to grab it. Wow. It looks good and it works. Here is the story in pictures...

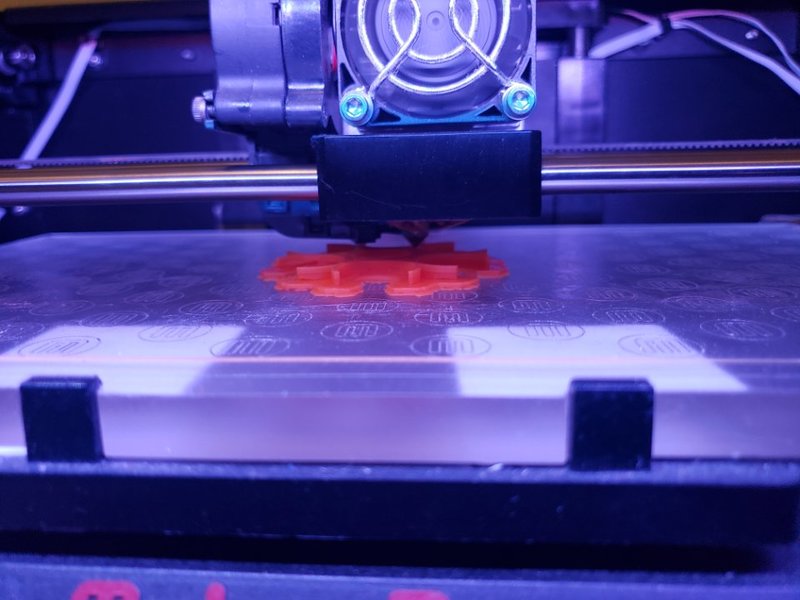

The print is just starting. The raft is down and you can just see the edges. I think it's at 4% here.

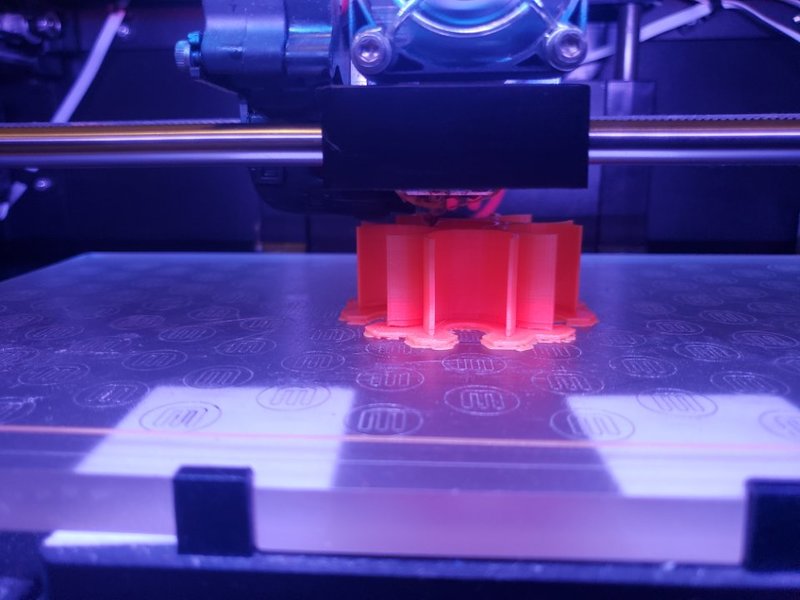

Here we are at 43%.

All done, but will the batteries fit?

Back at home, I tried the batteries. Wow. It's awesome to see how they clip in. It feels solid.

The view from the top. There's some cracking I don't understand. Maybe Guru Chris can clue me in.

@cerich should see this.

The print is just starting. The raft is down and you can just see the edges. I think it's at 4% here.

Here we are at 43%.

All done, but will the batteries fit?

Back at home, I tried the batteries. Wow. It's awesome to see how they clip in. It feels solid.

The view from the top. There's some cracking I don't understand. Maybe Guru Chris can clue me in.