You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Argonaut Kraken exhaust loop flooding issue...?

- Thread starter Fibonacci

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Watching this for ideas. My Kraken hasn't given me issues, but my DA with all the upgrades has been a "trickle leaker" for the last two years. I rebuilt the DSV, so I hope that is the solution. A little fresh water is a nuisance, but salt water is just plain nasty. It has caused me to gag a few times. Will see in December as it heads back to Curacao.

Keep this discussion going.....

Keep this discussion going.....

Will do@lexvil when you do your tests, for consistency could you also please try the position I encountered my leaks?

Body horizontal, head slightly down, breath cycle paused after having exhaled

OK quick update after a couple of great dives out at Montague Island, on the far south coast of NSW.

Water temp 19-21C viz about 20m and lots of marine life including a big Grey Nurse shark, two Wobbegong sharks, rays and plenty of playful seals. We went with Underwater Safaris.

The Kraken caused a great deal of interest, most divers had no idea what it was and thought it was either some sort of integrated BC or a new type of rebreather (!)

Dive 1 was to 24m for 41mins, tried the Kraken in all types of positions, incl the one the caused consistent exhaust loop flooding last time. All good, dry breathing... seemed the resurfaced exhaust seat had fixed the problem! Feeling happy...

Surface interval 1:15mins with hot drinks, home baked muffins and fresh fruit. Nice touch!

Dive 2 was to 22m for 47mins

Initially dry breathing but started breathing a little wet about 15 mins into the dive. Purged and exhaled while rolling left to clear the loop which seemed to work.

No exhaust loop flooding but it did seem to breathe inconsistently while swimming along at the same depth for the second dive.

Some breaths were effortless (felt like 0.5”) while others felt more like 1.5”. Not sure what caused this... every hose connection point seemed tightly clamped and the DSV had brand new o-rings! The Kraken cracked at 0.7” on my 0-3” Magnehelic after it came back from being serviced at VDH.

So it seems the primary exhaust loop flooding issue was definitely due to the distorted exhaust seat surface.

I need to do some more dives to determine if the wet breathing was just a one off or there is some other cause.

When performing properly I very much enjoy diving the Kraken, marine life really does allow you to approach closer and I love the lack of bubbles across your vision and relative quietness vs single hose regs!

Water temp 19-21C viz about 20m and lots of marine life including a big Grey Nurse shark, two Wobbegong sharks, rays and plenty of playful seals. We went with Underwater Safaris.

The Kraken caused a great deal of interest, most divers had no idea what it was and thought it was either some sort of integrated BC or a new type of rebreather (!)

Dive 1 was to 24m for 41mins, tried the Kraken in all types of positions, incl the one the caused consistent exhaust loop flooding last time. All good, dry breathing... seemed the resurfaced exhaust seat had fixed the problem! Feeling happy...

Surface interval 1:15mins with hot drinks, home baked muffins and fresh fruit. Nice touch!

Dive 2 was to 22m for 47mins

Initially dry breathing but started breathing a little wet about 15 mins into the dive. Purged and exhaled while rolling left to clear the loop which seemed to work.

No exhaust loop flooding but it did seem to breathe inconsistently while swimming along at the same depth for the second dive.

Some breaths were effortless (felt like 0.5”) while others felt more like 1.5”. Not sure what caused this... every hose connection point seemed tightly clamped and the DSV had brand new o-rings! The Kraken cracked at 0.7” on my 0-3” Magnehelic after it came back from being serviced at VDH.

So it seems the primary exhaust loop flooding issue was definitely due to the distorted exhaust seat surface.

I need to do some more dives to determine if the wet breathing was just a one off or there is some other cause.

When performing properly I very much enjoy diving the Kraken, marine life really does allow you to approach closer and I love the lack of bubbles across your vision and relative quietness vs single hose regs!

Thank you for the update-that's great news.

In rinsing out the gear and packing up I removed the hoses from the can, plugged the intake end and test breathed through the still connected DSV. Yes, I did check it was fully open!

There is a slight air leak, need to do more checks on whether it is coming under the hose clamps or via the DSV o-rings. Source of the wet breathing!

So I suspect the intake leak would also cause variable tension on the main diaphragm and therefore account for the variable WOB I encountered on the second dive.

Now that I have solved the mystery of the exhaust loop flooding I can turn to this final niggle!

More to come

There is a slight air leak, need to do more checks on whether it is coming under the hose clamps or via the DSV o-rings. Source of the wet breathing!

So I suspect the intake leak would also cause variable tension on the main diaphragm and therefore account for the variable WOB I encountered on the second dive.

Now that I have solved the mystery of the exhaust loop flooding I can turn to this final niggle!

More to come

OK back home now and following up on the wet breathing issue...

I removed the DSV from the loop and blocked off the inlet side (valve still in place) slight air leak.

Removed the inlet valve assembly and retried... still leaking.

Removed mouthpiece and retried... still leaking!

Disassembled DSV and discovered one of the new o-rings had developed a small nick in the centre, seems to be catching up on the sharp inner edge of the orifice during rotation?

Thinking at last this was the aha moment and a simple cause of the wet breathing issue, I replaced the -028 o-ring and reassembled the DSV.

Cycled the DSV open and closed 50 times then disassembled and checked the o-ring... no nicks!

Reassembled and checked...

STILL a slight air leak, seems to be getting past these brand new o-rings

I removed the DSV from the loop and blocked off the inlet side (valve still in place) slight air leak.

Removed the inlet valve assembly and retried... still leaking.

Removed mouthpiece and retried... still leaking!

Disassembled DSV and discovered one of the new o-rings had developed a small nick in the centre, seems to be catching up on the sharp inner edge of the orifice during rotation?

Thinking at last this was the aha moment and a simple cause of the wet breathing issue, I replaced the -028 o-ring and reassembled the DSV.

Cycled the DSV open and closed 50 times then disassembled and checked the o-ring... no nicks!

Reassembled and checked...

STILL a slight air leak, seems to be getting past these brand new o-rings

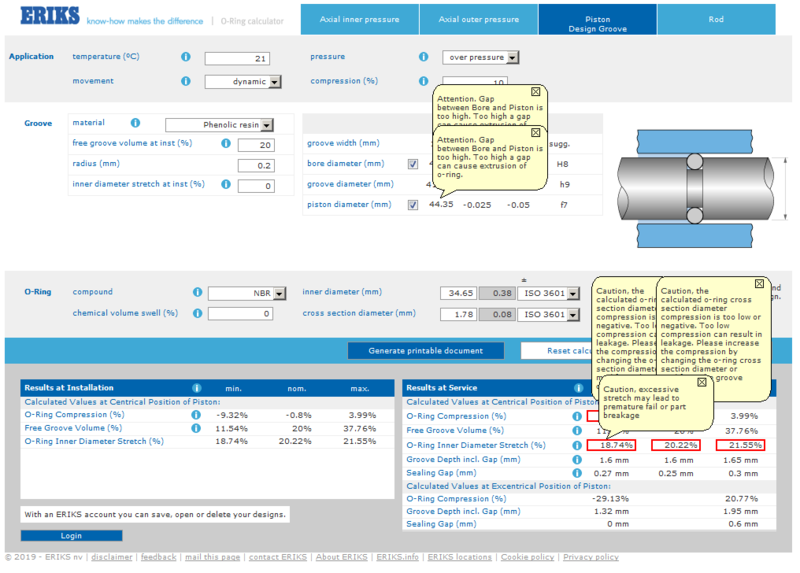

Pulled down the DSV and measured everything...

Bore of outer housing 44.86mm

External diameter of inner tube 44.35mm

(clearance 0.51mm)

O-ring groove width 2.2mm

O-ring groove inner diameter 41.60mm

-028 o-ring specifications ID 34.65mm x 1.78mm CS

On a hunch I ran the o-ring calculator at Eriks:

ERIKS O-Ring Calculator

Seems there may be too much clearance between components, so not enough o-ring compression to seal consistently around the full diameter?

These DSV's seem finicky when it comes to o-rings, but a dynamic assembly needs some running clearance.

Trying to eliminate the cause of possible air leak paths...

Bore of outer housing 44.86mm

External diameter of inner tube 44.35mm

(clearance 0.51mm)

O-ring groove width 2.2mm

O-ring groove inner diameter 41.60mm

-028 o-ring specifications ID 34.65mm x 1.78mm CS

On a hunch I ran the o-ring calculator at Eriks:

ERIKS O-Ring Calculator

Seems there may be too much clearance between components, so not enough o-ring compression to seal consistently around the full diameter?

These DSV's seem finicky when it comes to o-rings, but a dynamic assembly needs some running clearance.

Trying to eliminate the cause of possible air leak paths...

Tried another test...

DSV exhaust and inlet valve assemblies in place, hoses and mouthpiece removed.

Blocked both inlet and exhaust sides and breathed in... this time the DSV assembly holds a hard vacuum so air must have been leaking in via the exhaust valve side!

Through the valve or wagon wheel o-ring... but the exhaust side of the loop is not directly exposed to water if the hose clamps are doing their job??

Edit to add:

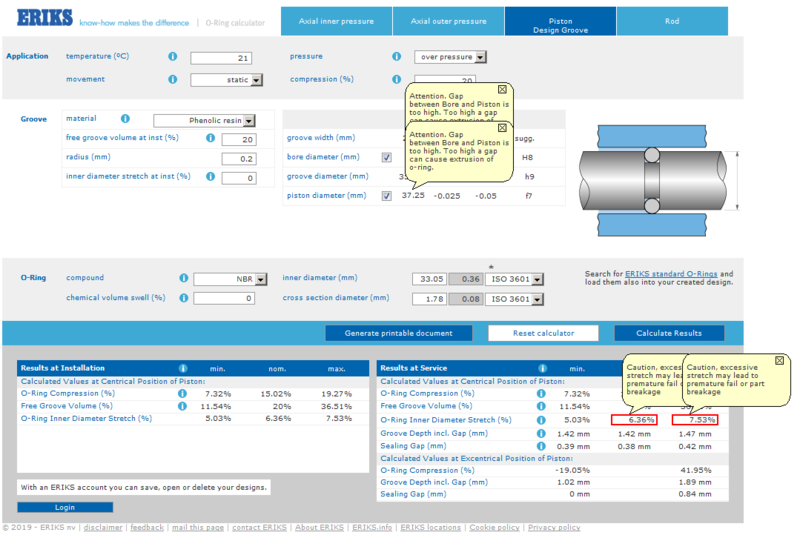

Bore in the inner DSV housing for wagon wheel is 38.0mm

Wagon wheel diameter is slightly egg shaped... 37.20mm at 90 deg to the partline, 37.28 across the partline (small amount of flash) so used 37.25mm

Wagon wheel groove width is 2.4mm

Wagon wheel groove diameter 34.50mm

-027 o-ring ID 33.05mm x 1.78mm

Running Eriks o-ring calculator again

DSV exhaust and inlet valve assemblies in place, hoses and mouthpiece removed.

Blocked both inlet and exhaust sides and breathed in... this time the DSV assembly holds a hard vacuum so air must have been leaking in via the exhaust valve side!

Through the valve or wagon wheel o-ring... but the exhaust side of the loop is not directly exposed to water if the hose clamps are doing their job??

Edit to add:

Bore in the inner DSV housing for wagon wheel is 38.0mm

Wagon wheel diameter is slightly egg shaped... 37.20mm at 90 deg to the partline, 37.28 across the partline (small amount of flash) so used 37.25mm

Wagon wheel groove width is 2.4mm

Wagon wheel groove diameter 34.50mm

-027 o-ring ID 33.05mm x 1.78mm

Running Eriks o-ring calculator again

TN Traveler

Contributor

Please keep us informed. Having similar issues!

Similar threads

- Replies

- 0

- Views

- 249

- Replies

- 3

- Views

- 980

- Replies

- 44

- Views

- 5,024