So, after the

tragic misprint of my 4S3P Battery Holder (Not to be confused with the box printing happily in the back ground), I knew I had to get into the CAD files and check my dimensions. This required remembering where I created them and how to actually use that program. All this angst! I was supposed to dive today, but my healing leg has another plan, so here I sit. With time on my hands and a failed print. I guess I'm going to have to dig in, so might as well get it over with... and here I go.

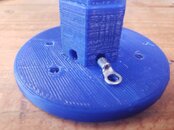

I remember designing the files to press together but these clearly won't. No, I didn't allow any clearance, but this is plastic, right? If it doesn't fit, just force it! I am using

www.Onshape.com and it took a few moments to get reoriented to using it this am. Wow, but the initial drawing I created was incredibly complex and detailed... at least for me. There was about a 1.5mm issue with the actual print (in the Red PLA that has issues). Thinking I might have made a mistake in the drawings I had to figure out how to measure but everything came out to be 18mm. My first thought was to modify the stepped base. Modifying one file should be easier than two, right? Nope. Multiple extrusions had locked that in, so I went to the two simpler files and enlarged the opening on each by 0.05 mm (0.002") for clearance sake. I also added camfers to everything to make it even easier to assemble. I'm going to try and print these in ABS when the battery box finishes later this am. One part at a time though. I might still have to adjust the fit a bit.

So, my fear of CAD is still there and still unfounded. I was pleased that after all these months, I retained enough to still get things done. The one thing that still sits with me today is how well Onshape was presented in their tutorials. Sitting down on a Sunday and having a working file by that afternoon still blows me away. I can't remember how many times I tried to figure out CAD and they made it easy. Way cool.

So the ugly red filament really has an issue and didn't maintain its dimensions. It might be temperature related, but the other filaments look fine.