Just don’t see the difference between balanced and unbalanced between these two regulators, supply pressure 1100 psi.

Are balanced regulators all what the manufactures say they are cracked up to be. No pun intended. Lol

What I’m I missing?

Average flow (SP spec’s) is not that much different, IP between 115, 118 in both cases while flowing. I understand the principles with balanced regulators... lighter spring, easier to breath, immune to small IP changes. But my testing just doesn’t seem to prove that out.

I’m loving the 108 simplicity and no adjustment knob that I never use anyway.

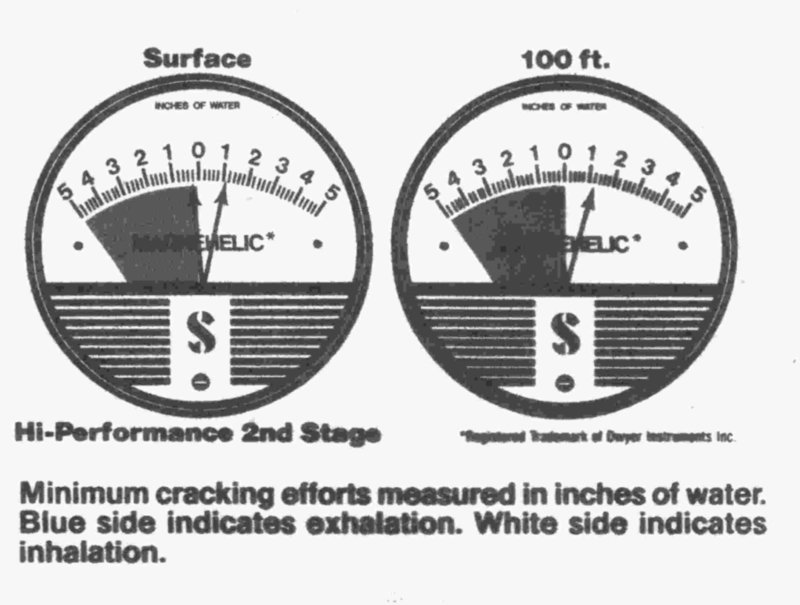

Flow test: 108HP

Cracking .7

5 SCFM H20 1.0

8 SCFM H20 1.1

10 SCFM H20 1.1

SP catalogue:

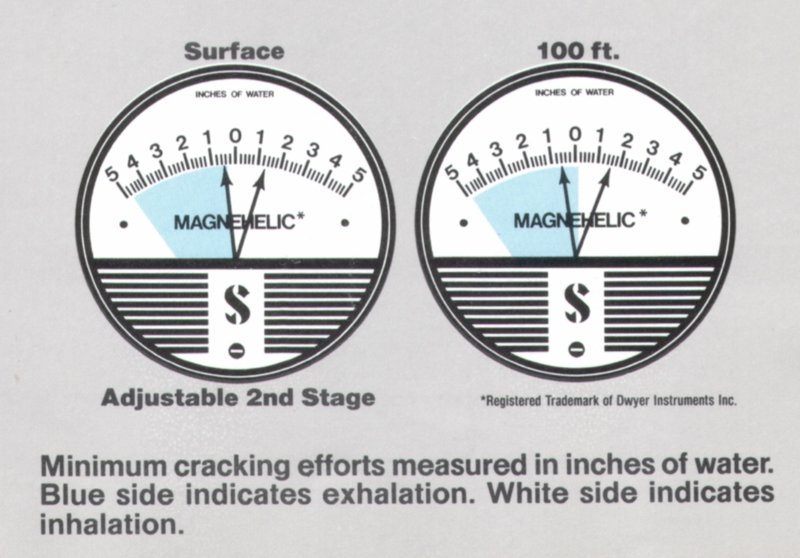

Flow test: BA156

Cracking .8

5 SCFM H20 1.0

8 SCFM H20 1.0

10 SCFM H20 1.4

SP catalogue:

Are balanced regulators all what the manufactures say they are cracked up to be. No pun intended. Lol

What I’m I missing?

Average flow (SP spec’s) is not that much different, IP between 115, 118 in both cases while flowing. I understand the principles with balanced regulators... lighter spring, easier to breath, immune to small IP changes. But my testing just doesn’t seem to prove that out.

I’m loving the 108 simplicity and no adjustment knob that I never use anyway.

Flow test: 108HP

Cracking .7

5 SCFM H20 1.0

8 SCFM H20 1.1

10 SCFM H20 1.1

SP catalogue:

Flow test: BA156

Cracking .8

5 SCFM H20 1.0

8 SCFM H20 1.0

10 SCFM H20 1.4

SP catalogue: