Yikes, you guys should build or buy your own x-ray machine. It's not super complicated.I often get parts x-rayed for work. The local place by me starts at $300 for two images with CR. Might as welwell just buy a new tank.

Homemade Xray Machine

There's lots of other plans available with differing ease of build and quality results. Obvious care is required to prevent unintended exposure but it's not really that hard to do.

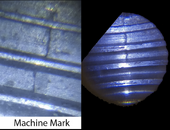

Armchair team owner here, I think the photo of the tank in question resembles that example tooling mark photo @GJC posted.