Interesting ideas John, I’ll take a look at this before my trip, we just may have a contributing factor here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Argonaut Kraken exhaust loop flooding issue...?

- Thread starter Fibonacci

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

I can see where these “ribs” may have been intended to address the problem that John has pointed out and with the stiffer material of the past may have been all that’s needed.Thanks for your insight... could well be a contributor.

The original pic earlier in this thread shows rub marks where both the exhaust valve and the stand off rib had been impacting the outside of the diaphragm quite hard. Suction when inhaling could affect the exhaust valve... but the standoff rib is meant to limit proximity of the two components.

The main flooding happened only in certain positions, but it did happen quite consistently:

Body horizontal, head slightly down, breath cycle paused after having exhaled

To me that indicates that sealing of the exhaust valve against the spider is the main cause... but perhaps not the only cause.

Is it a case geometry issue as well?

Surface area of the exhaust mushroom valve vs captured volume in the exhaust hose overcoming clamp force and lifting an edge? The hose flooded in about 15 seconds so quite a volume of water entered.

The Nemrod Snark III has a huge exhaust valve with an integral central standoff boss and two pins for example...

View attachment 514685

View attachment 514686

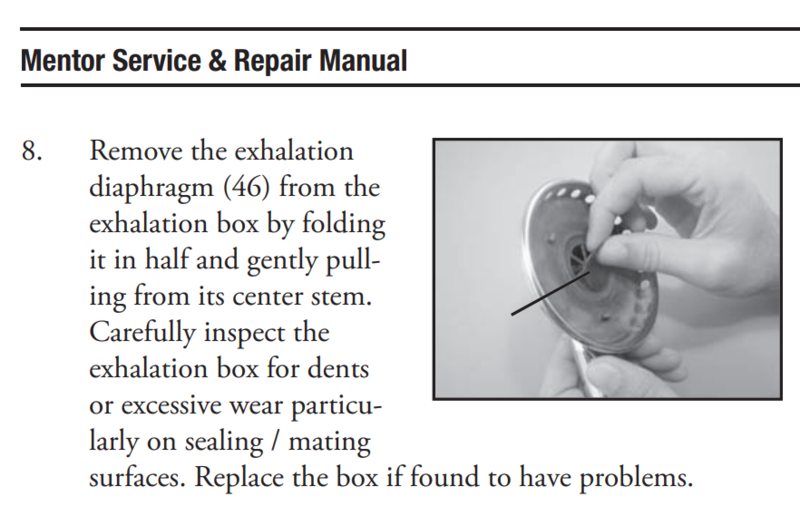

Compare to the Aqualung Mentor with three radial standoff pins for the diaphragm

View attachment 514695

Will do more tests over the break and add to whatever @couv and @lexvil may find out...

There is a plastic physical barrier already in place that doesn’t allow the diaphragm from touching the exhaust valve when the valve is closed.

The only time the valve can contact the diaphragm is when the diver is exhaling. The valve is open at that moment. The valve sealing surface is also slightly sloped down away from the diaphragm. This was intentionally done so that the two surfaces would not be parallel, so that when the valve open and touched the diaphragm the contact would be uneven.

I have an exhaust can that we intentionally cut a viewing port to observe the interaction between the diaphragm and the exhaust can. If you do a search you can probably find pictures of the pool dives I did with the test can.

The diaphragm in all my Argonauts (and everyone else I have seen) has marks from the plastic stand-off and also from the valve. The marks from the valve are happening due the contact during exhalation. During my observations, that is the only time I have seen the exhaust valve touch the diaphragm.

The only time the valve can contact the diaphragm is when the diver is exhaling. The valve is open at that moment. The valve sealing surface is also slightly sloped down away from the diaphragm. This was intentionally done so that the two surfaces would not be parallel, so that when the valve open and touched the diaphragm the contact would be uneven.

I have an exhaust can that we intentionally cut a viewing port to observe the interaction between the diaphragm and the exhaust can. If you do a search you can probably find pictures of the pool dives I did with the test can.

The diaphragm in all my Argonauts (and everyone else I have seen) has marks from the plastic stand-off and also from the valve. The marks from the valve are happening due the contact during exhalation. During my observations, that is the only time I have seen the exhaust valve touch the diaphragm.

Luis, I seem to remember a fence and the slope of the DBE, I tend to dive perhaps a little differently, using long slow exhales, do you think it’s possible that my technique/habit could cause a slight “pull” against the DBE mushroom with a sudden inhale?

Long slow exhales are fairly typical for many DH regulator users...

With the mushroom valve closed, the plastic stop will not let the diaphragm come in contact with the valve. It doesn't matter if either is was moving fast or slow. There is a physical stop that provides a clearance between the two. The only time the valve will touch the diaphragm is when the valve is open. If you exhale fast or hard you may open the valve more, but that would be the opposite of what you are suggesting.

With the mushroom valve closed, the plastic stop will not let the diaphragm come in contact with the valve. It doesn't matter if either is was moving fast or slow. There is a physical stop that provides a clearance between the two. The only time the valve will touch the diaphragm is when the valve is open. If you exhale fast or hard you may open the valve more, but that would be the opposite of what you are suggesting.

Ok, even with the designers assurance that this isn’t necessary I thought I would give the SeaRat idea a try. I went looking for something that would match the DBE radius that could be tested but removed easily, found some pipe insulation and using a razor blade did some cutting

Trimmed it to the same height as the existing stop and cut a relief so the mushroom can move freely. Using some rtv I’ve glued it in place and once set I’ll put it back together.

I could pool test it later today if I get a few moments.

Trimmed it to the same height as the existing stop and cut a relief so the mushroom can move freely. Using some rtv I’ve glued it in place and once set I’ll put it back together.

I could pool test it later today if I get a few moments.

Took it for a short pool dive, meaningless overall but at least I know everything works.

Thanks guys. Good info. But, I think we're jumping too many squares ahead. I'm a bit concerned that rather than trying one "fix" at a time, we won't be able to nail down exactly what the problem/solution is.

It is very possible the issue is caused by improper seating of the mushroom valve due to a less than perfect significant sealing surface (caused by the molding process) and/or the mushroom valve itself. Lex/Fibonacci and Luis have all pointed to that area.

Thanks, I look forward to your updates.

It is very possible the issue is caused by improper seating of the mushroom valve due to a less than perfect significant sealing surface (caused by the molding process) and/or the mushroom valve itself. Lex/Fibonacci and Luis have all pointed to that area.

Thanks, I look forward to your updates.

@couv it would seem the sealing surface on the Kraken is quite narrow compared with other similar design executions, so any surface anomalies would be more critical.

See the Mentor, seems to have a larger exhaust valve diameter, more spokes on the spider for centre support and the sealing surface is also protected by a continuous circular raised rib and the three standoffs.

https://www.flashbackscuba.com/museum/Aqualung Mentor/Mentor Repair Manual.pdf

See the Mentor, seems to have a larger exhaust valve diameter, more spokes on the spider for centre support and the sealing surface is also protected by a continuous circular raised rib and the three standoffs.

https://www.flashbackscuba.com/museum/Aqualung Mentor/Mentor Repair Manual.pdf

My recent tidbit is easily removable, I think I got it solved by lapping the seating surface, if I get several noflood dives I’ll remove the extra piece and try it again. For me the flooding was always intermitant so it’s hard to really know if it’s solved until a lot of dives are done.Thanks guys. Good info. But, I think we're jumping too many squares ahead. I'm a bit concerned that rather than trying one "fix" at a time, we won't be able to nail down exactly what the problem/solution is.

It is very possible the issue is caused by improper seating of the mushroom valve due to a less than perfect significant sealing surface (caused by the molding process) and/or the mushroom valve itself. Lex/Fibonacci and Luis have all pointed to that area.

Thanks, I look forward to your updates.

Similar threads

- Replies

- 0

- Views

- 157

- Replies

- 3

- Views

- 956

- Replies

- 44

- Views

- 5,006