Doctor Rig

Contributor

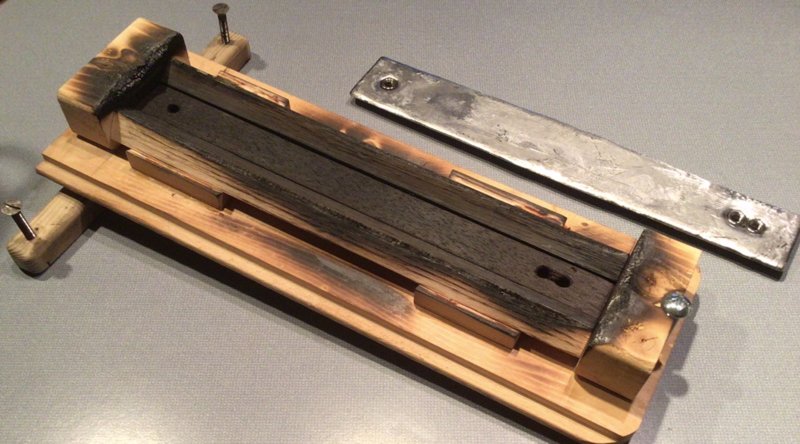

Utilizing lead casting information that I could find, I’ve just made my first P-weight. I made and used an oak mold and inserted 5/16-18 flanged nuts embedded in the lead for attachment. This P-weight is 3/8 thick by 13 inches long and weighs 3 pounds 8 ounces, which was my desired target size & weight.

Mold & P-weight

P-weight

My DIY learnings may be of help if you want to try it yourself.

I learned from @michael-fisch that it is helpful to keep the lead surface hot with a torch to prevent sink marks and create a relatively smooth surface. This worked extremely well, but I was surprised how long i had torch the surface, as it took longer than I expected for the lead to cool off/solidify.

The oak mold worked well molding my P-weight, but using a torch as mentioned chars the exposed wood as you can see in the pictures.. Otherwise my wood mold could have been used for multiple pours. (Thank goodness I only wanted one.)

I created the mold using three pieces of oak fitted together. The interface between these pieces of wood caused some small leaks and bubbles coming up through the mold while it cooled off. A one piece wood mold would have eliminated these issues and saved me the time required to remove the excess lead at the interface.

I melted my lead using a little Coleman stove and and handheld propane torch. Upon melting the lead, I fluxed the lead with sawdust and removed the impurities that were on the molten lead surface just before pouring.

For mold set up, I added three screws leveling the mold which worked well and also used them to further level the lead after pouring.

If anyone more knowledgeable in molding P-weights, feel free to add your DIY advice/recommendations too.

Fun little project, but you must love doing things like this, as it took a bit of time.

Mold & P-weight

P-weight

My DIY learnings may be of help if you want to try it yourself.

I learned from @michael-fisch that it is helpful to keep the lead surface hot with a torch to prevent sink marks and create a relatively smooth surface. This worked extremely well, but I was surprised how long i had torch the surface, as it took longer than I expected for the lead to cool off/solidify.

The oak mold worked well molding my P-weight, but using a torch as mentioned chars the exposed wood as you can see in the pictures.. Otherwise my wood mold could have been used for multiple pours. (Thank goodness I only wanted one.)

I created the mold using three pieces of oak fitted together. The interface between these pieces of wood caused some small leaks and bubbles coming up through the mold while it cooled off. A one piece wood mold would have eliminated these issues and saved me the time required to remove the excess lead at the interface.

I melted my lead using a little Coleman stove and and handheld propane torch. Upon melting the lead, I fluxed the lead with sawdust and removed the impurities that were on the molten lead surface just before pouring.

For mold set up, I added three screws leveling the mold which worked well and also used them to further level the lead after pouring.

If anyone more knowledgeable in molding P-weights, feel free to add your DIY advice/recommendations too.

Fun little project, but you must love doing things like this, as it took a bit of time.