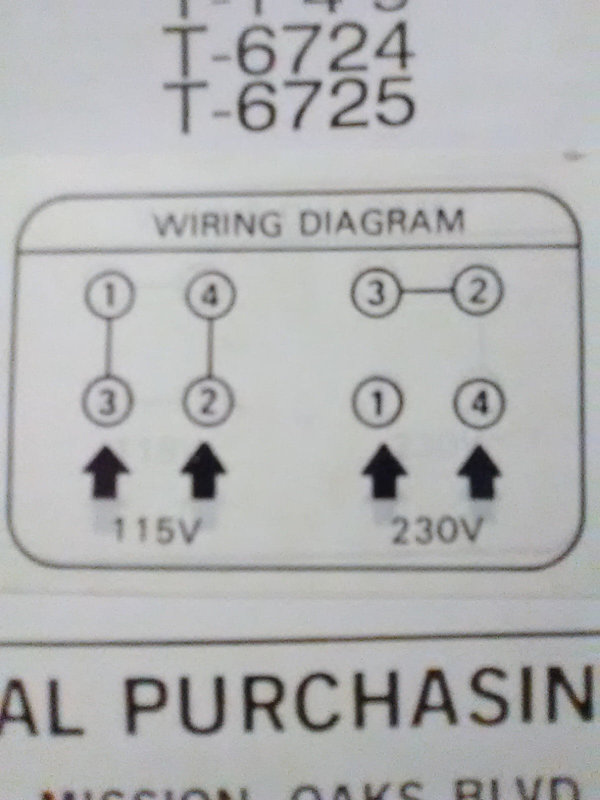

So I picked up another shop compressor to run my booster. I has a 3hp 120/240V motor on it. Unfortunately the wiring sticker is worn away so I can't tell if it's jumpered for 120v or jumpered for 240v. The 4 terminals are not labelled at all. How can I tell these apart with a multimeter?

(it has 2 capacitors on top if it matters)

(it has 2 capacitors on top if it matters)