The Chairman

Chairman of the Board

I've been completely frustrated in the past with my Tevo Tornado. I had it running with an OctoPi, but it was plagued with problem after problem, to the point I just stopped printing. Meh. So, I decided two years ago to update to the Duet 2. Life happened and I broke my leg while in Fiji. Finally, I'm ready to do this. This past week has seen most of it go together, but I still have some unresolved issues. I also want to change my extruder/hot end duo to a single unit. This will allow me to print both softer and harder materials. Please feel free to comment and kibbitz on my approach.

While I've always been fastidious about crimping, I had to up my game to make these cables. There are three different cable ends used in this project, and all my crimpers were for much bigger connectors. I bought two Iwiss crimpers, with my favorite being the stepped crimper. It will crimp the wire at one size and the insulation at another. On the JST-PH connectors, I had to use tweezers, they were so small. Each connector had its own methodology and this was indeed tedious.Many thanks to my friends at the Gainesville Hackerspace. They've already have given me some creat insight and direction.

The new Iwiss is thin to deal with these tiny connectors

The tools I used to do all the crimping

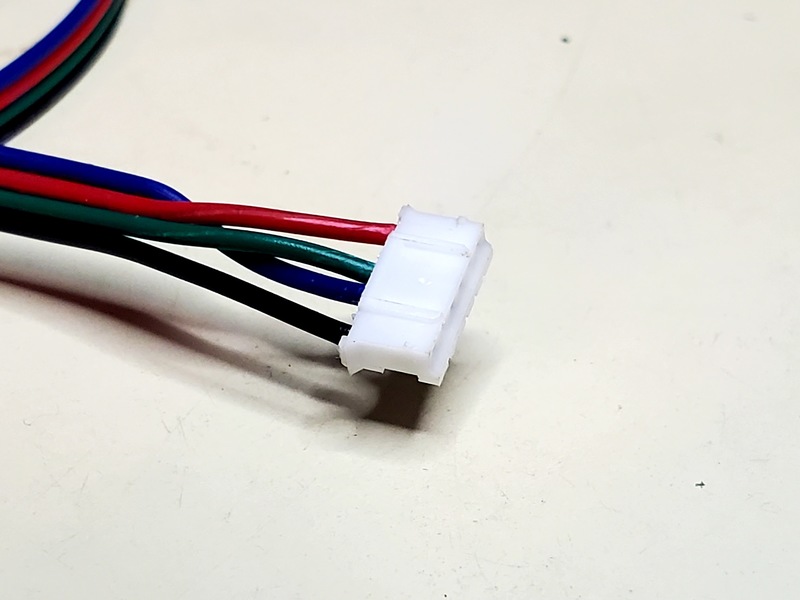

A JST-PH connector

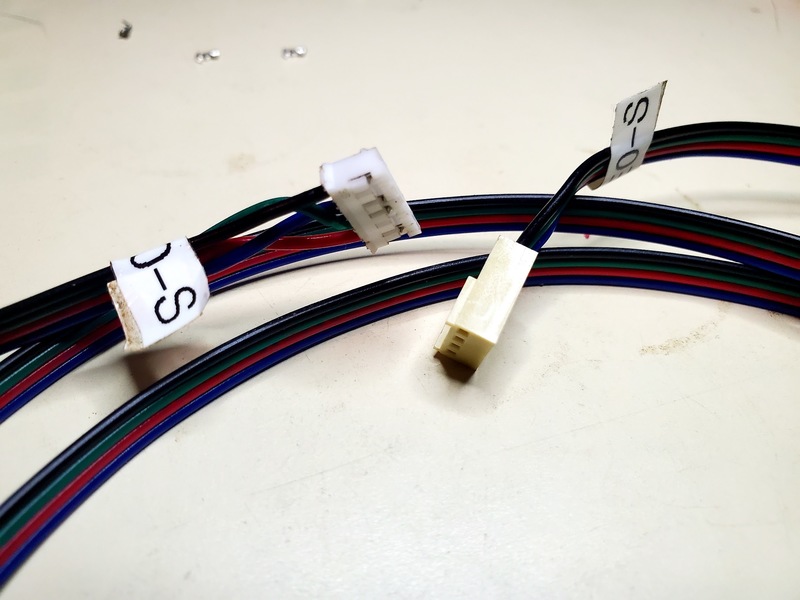

Labels are important as the wires all look the same

I had taken care to measure the old cables and added 6". I also had to add another 22" for the extruder stepper motor. Finally, I labeled each cable on either end.

While I've always been fastidious about crimping, I had to up my game to make these cables. There are three different cable ends used in this project, and all my crimpers were for much bigger connectors. I bought two Iwiss crimpers, with my favorite being the stepped crimper. It will crimp the wire at one size and the insulation at another. On the JST-PH connectors, I had to use tweezers, they were so small. Each connector had its own methodology and this was indeed tedious.Many thanks to my friends at the Gainesville Hackerspace. They've already have given me some creat insight and direction.

The new Iwiss is thin to deal with these tiny connectors

The tools I used to do all the crimping

A JST-PH connector

Labels are important as the wires all look the same

I had taken care to measure the old cables and added 6". I also had to add another 22" for the extruder stepper motor. Finally, I labeled each cable on either end.