amarti2038

Registered

- Messages

- 17

- Reaction score

- 0

Ok, now the compresor works fine. The error was that my brother changed the safety valve trim and the valve was always open. Yesterday I found that and I re-trim it again while charging a test tank. I just started to charge the tank clossing the valve ussing a screen driver with the trimming screw, every time it was open due pressure i closed it a bit more till 225 bars where I set it definetly. It really helped a draft draw that i found in internet.

After trimming the safety valve I started to perform some testing tanks.

- Air taste: normal

- Filling rate: 146L/min (two 15L tanks in 46 minutes at 225 bars) theorical rate for our compresor block 140L/min

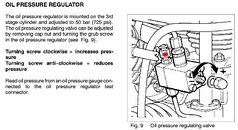

- Oil pressure: 60 bars 10 bars over the recomended value (50 bars are the bauer manual recomended value)

- Air/oil leaks: I found a small air leak in one of the filling hose at max pressures and a minimum leak of oil in the 3rd stage intake, but it is minimal, I could only notice because the piece was humid and can be caused due the 10bars pressure excess, I will retrim the pressure with the oil pressure trimming screew to fix it at 55bars.

- O-rings state: the safety valve orings are just fine, there is no leak.

I will post some photos of the test later.

Regards,

Albert.

After trimming the safety valve I started to perform some testing tanks.

- Air taste: normal

- Filling rate: 146L/min (two 15L tanks in 46 minutes at 225 bars) theorical rate for our compresor block 140L/min

- Oil pressure: 60 bars 10 bars over the recomended value (50 bars are the bauer manual recomended value)

- Air/oil leaks: I found a small air leak in one of the filling hose at max pressures and a minimum leak of oil in the 3rd stage intake, but it is minimal, I could only notice because the piece was humid and can be caused due the 10bars pressure excess, I will retrim the pressure with the oil pressure trimming screew to fix it at 55bars.

- O-rings state: the safety valve orings are just fine, there is no leak.

I will post some photos of the test later.

Regards,

Albert.