Jim B diving his Argonaut Kraken with the new DSV mouthpiece in Lake Michigan on Saturday

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project Argonaut, totally new, vintage style DH regulator

- Thread starter Luis H

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

I am planning on posting a new thread at VDH soon on how to take full advantage of the new Argonaut DSV with the flow diverter.

You can just use DSV as it is (with any double hose regulator), but by adjusting the Argonaut you can truly kick the performance up a few notches. There is nothing magical to the adjustment, most divers should be able to do it.

It is the same basic adjustments to lower the cracking effort down below 1 inWC (close to 0.7 inWC) and then the most important is to increase the venturi flow.

Increasing the venturi flow effect in the Argonaut is easy. You just need to block the two side bleed holes on the second stage. It is really that simple.

If everything is tuned properly, the only change is to block both of the side ports. That alone will induced a very good and very repeatable venturi flow during inhalation.

The venturi flow in combination with a low cracking suction will sustain the air flow while there is any demand. The diverter will not allow any air flow to be waster out the exhaust. But I have observed that the inhalation effort is nonexistent once flow is initiated.

For those who want the ultimate in performance, there are a few checks that the owner may want to make, to optimize the regulator. Some things are easy to check and adjust, like lever height and IP. The cracking effort is not hard to measure if you have the right set-up.

I hope to have more next week.

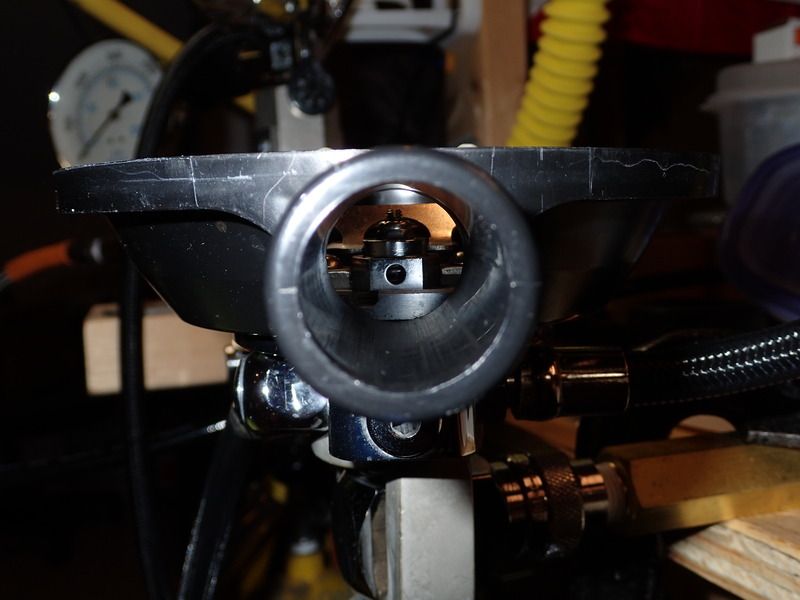

Here I am showing one side blocked

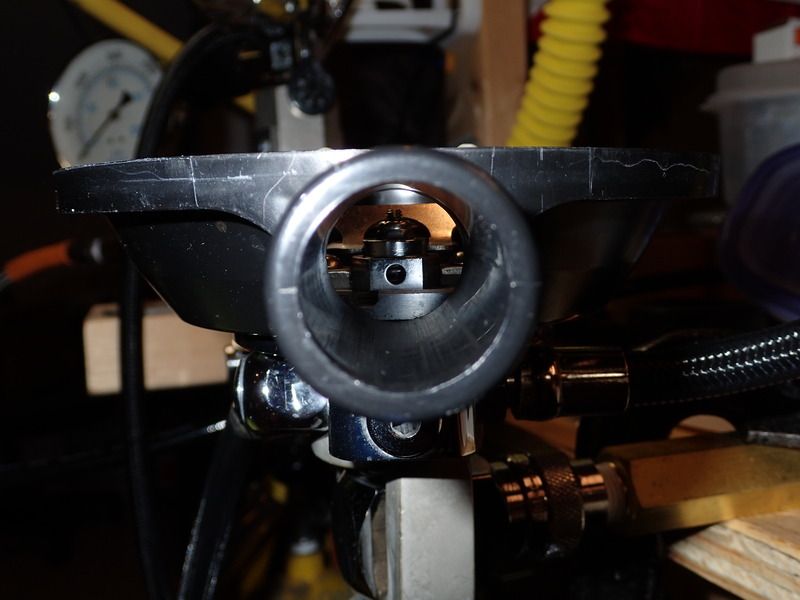

Other side:

Both:

This gives you an indication of the lever height, but I will expand on this more later. You should not need to do anything with the lever height. It should be fine, but I will explain how to check it later. I am just using the scale as a straight edge.

I am pressing a bit with my Mistral tool. Again, more later.

The nozzle points down the full diameter horn. The nozzle flow forms a cone. That is why I designed the can with a full circular tube horn.

The vintage metal cans are attractive and they work well, but the rectangular horn base is not ideal to develop maximum venturi flow. They are good enough for most flow rates, but the Argonaut can was optimized for all flow rates and the DSV flow diverter is essential to take advantage of the maximum venturi flow.

This can was optimized for production (with the soldered or brazed horns) not for flow performance. The rectangular horn base is the same as in the early Broxton regulators with no induced venturi flow at all.

A full sized circular tube horn would have been much more difficult to attach with a clean transition on this can.

I will be adding more later and I will probably separate this post into a new thread talking about optimizing the overall Argonaut performance, but I needed to provide some advance information.

I hope this helps.

You can just use DSV as it is (with any double hose regulator), but by adjusting the Argonaut you can truly kick the performance up a few notches. There is nothing magical to the adjustment, most divers should be able to do it.

It is the same basic adjustments to lower the cracking effort down below 1 inWC (close to 0.7 inWC) and then the most important is to increase the venturi flow.

Increasing the venturi flow effect in the Argonaut is easy. You just need to block the two side bleed holes on the second stage. It is really that simple.

If everything is tuned properly, the only change is to block both of the side ports. That alone will induced a very good and very repeatable venturi flow during inhalation.

The venturi flow in combination with a low cracking suction will sustain the air flow while there is any demand. The diverter will not allow any air flow to be waster out the exhaust. But I have observed that the inhalation effort is nonexistent once flow is initiated.

For those who want the ultimate in performance, there are a few checks that the owner may want to make, to optimize the regulator. Some things are easy to check and adjust, like lever height and IP. The cracking effort is not hard to measure if you have the right set-up.

I hope to have more next week.

Here I am showing one side blocked

Other side:

Both:

This gives you an indication of the lever height, but I will expand on this more later. You should not need to do anything with the lever height. It should be fine, but I will explain how to check it later. I am just using the scale as a straight edge.

I am pressing a bit with my Mistral tool. Again, more later.

The nozzle points down the full diameter horn. The nozzle flow forms a cone. That is why I designed the can with a full circular tube horn.

The vintage metal cans are attractive and they work well, but the rectangular horn base is not ideal to develop maximum venturi flow. They are good enough for most flow rates, but the Argonaut can was optimized for all flow rates and the DSV flow diverter is essential to take advantage of the maximum venturi flow.

This can was optimized for production (with the soldered or brazed horns) not for flow performance. The rectangular horn base is the same as in the early Broxton regulators with no induced venturi flow at all.

A full sized circular tube horn would have been much more difficult to attach with a clean transition on this can.

I will be adding more later and I will probably separate this post into a new thread talking about optimizing the overall Argonaut performance, but I needed to provide some advance information.

I hope this helps.

george_austin

Contributor

- Messages

- 573

- Reaction score

- 289

- # of dives

- 5000 - ∞

Notice he is wearing Force Fins.

I found a set on CL at a greatly reduced cost but brand new - I seriously doubt I'll use any of my other fins - take a dive or two to get used to but pretty amazing

Similar threads

- Replies

- 21

- Views

- 1,112

- Replies

- 1

- Views

- 861