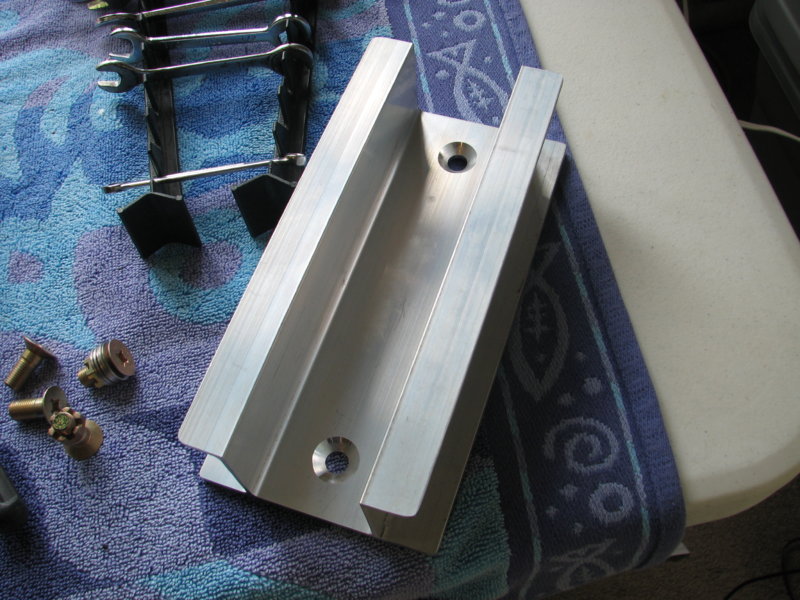

Say hello to my new toy.

I had a friend cut a piece of scrap U channel aluminium so I could make a regulator holding fixture. After a bit of time smoothing the sharp edges, drilling and countersinking holes for mounting to my work bench-add a few strips of sticky back fuzzy Velcro and voila! No more need for screwing in a regulator holding tool and chucking it up in a vice. What a time saver.

I had a friend cut a piece of scrap U channel aluminium so I could make a regulator holding fixture. After a bit of time smoothing the sharp edges, drilling and countersinking holes for mounting to my work bench-add a few strips of sticky back fuzzy Velcro and voila! No more need for screwing in a regulator holding tool and chucking it up in a vice. What a time saver.

Attachments

Last edited: