You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tank whips (not transfer whips)

- Thread starter duckbill

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Peter_C

Contributor

What are you trying to accomplish? Also at what PSI?

Peter_C

Contributor

Broken board...

Bubbletrubble

Contributor

I think duckbill is trying to remove flash rust or bayerite from inside his tank without doing a full-on tumble.What are you trying to accomplish? Also at what PSI?

The job would be done at 1 ata.

I'll be watching this thread since I'm interested in making one as well. If I'm feeling too lazy when the time comes, I'll just buy the one that's sold by Northeast Scuba Supply.

oxyhacker made this post several years ago in a SB thread:

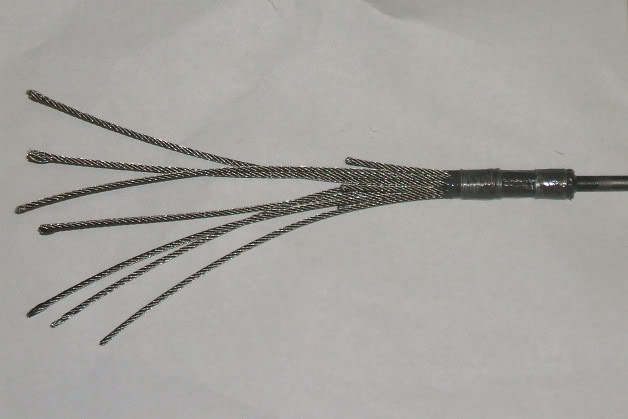

What you need, as others have pointed out, is a whip. Let's you do a light derusting anytime you like, and also useful if you ever get into O2 cleaning. You can buy them, but they are really easy to make. Take some braided steel cable (preferably stainless), like the stuff they sell for garage doors, and hose clamp a bunch of 18" to 24" lengths (doubled over) to ta 30" or so 5/16" or so steel or aluminum rod. Get a 1/2" NPT pvc bushing from the hardware store, screw it into the neck of the tank, chuck the whip into a drill, and flail away. Can be used wet or dry, or even with a phosphoric acid solution for more serious rust.

Peter_C

Contributor

Duh! Not sure why my mind didn't go to a cleaning whip. Here I started thinking he was trying to use it as a chamber for a low pressure air compressor or something.

The challenge with making a whip is the hose clamp is going to add a lot of bulk. I am not sure mine would fit thru a 1/2" neck. The store bought ones might fit, but they are around $70 or something. Chemicals would do a bang up job, and tumbling of course would get it cleaned out too.

The challenge with making a whip is the hose clamp is going to add a lot of bulk. I am not sure mine would fit thru a 1/2" neck. The store bought ones might fit, but they are around $70 or something. Chemicals would do a bang up job, and tumbling of course would get it cleaned out too.

R

redacted

Guest

I'm looking for good info also. Perhaps SS zip ties and some JB Weld could be used to make the attachment with minimal bulk. What are you using for the whip strands?

What are you using for the whip strands?

I'm open to suggestions. I was hoping to use 1/8" SS cable, but even with a 1/4" rod we are now approaching 1/2" overall. A hose clamp would definitely be out of the question. I keep hearing about braided cable, but all I can find is twisted, even for garage door cable.

I've never heard of stainless zip ties. I'll look into those. Thanks.

I've heard of guys using weed whacker line, but I don't know if that would do an adequate job by itself. The commercial whip lines are coated with an abrasive. Does anyone know how many cylinders can be whipped with one of those before it wears out?

Peter_C

Contributor

Awap, your idea of a different type of clamp might just lay flat enough. Like the one pictured below for a CV boot (It technically does use a special tool, but I own one). For the wire I just go to Home Depot and get stainless steel wire rope cut to the lengths I want. Their hydro cutting machine makes short work of it. The length is determined by the width of the tanks. I untwist the end a little to let it flare. The rod I used was aluminum, but brass works great. To protect my tank neck threads, I just use a plastic plug with a hole cut in it. I typically use my corded 1/2 drill.

R

redacted

Guest

I picked some up at Home Depot that were a bit simpler. Look like these: Stainless Steel Cable Ties - Stays Strong in the Face of Even the Harshest Environments

I am also thinking something like an arrow shaft with the whip strands in place of the point held in place with JB Weld. How about an old spear gun shaft?

I am also thinking something like an arrow shaft with the whip strands in place of the point held in place with JB Weld. How about an old spear gun shaft?

Thanks, guys. I incorporated your ideas into the whip I made today.

Awap, I found the SS cable ties at Home Depot like you show and bought them, but was afraid that even they might end up being too big to go in the 1/2" neck. I found out later that they may have been fine.

I ended up using 24 gauge galvanized steel wire and J-B Weld to lash 3/32" SS cable onto a 1/4" steel rod. I rounded the end of the rod in case it contacts the end of the cylinder so it wouldn't do any damage in case it touches it.

I was able to fit eleven pieces of 3/32" cable around the 1/4" rod. I used seven long pieces (9") and four short pieces (4", to help get the bottom of the cylinder). I used J-B Weld throughout the process, and whipped it all together with the 24 gauge wire at two points. There is less than $10 of material in this whip.

It fits in the 1/2" opening no problem. I may have been able to use the SS cable ties after all, or been able to use 1/8" cable with the whip knot method. However, I wouldn't have been able to get as many 1/8" cable pieces around the 1/4" rod as I was able to fit using 3/32" cable. I can see that a tube to help start the whip cables into the neck would be handy, especially once the cables get frayed.

Now I just need to let the J-B cure and get a tube to attach to my air nozzle to blow the dust out, and I'll be ready to whip it, whip it good.

Awap, I found the SS cable ties at Home Depot like you show and bought them, but was afraid that even they might end up being too big to go in the 1/2" neck. I found out later that they may have been fine.

I ended up using 24 gauge galvanized steel wire and J-B Weld to lash 3/32" SS cable onto a 1/4" steel rod. I rounded the end of the rod in case it contacts the end of the cylinder so it wouldn't do any damage in case it touches it.

I was able to fit eleven pieces of 3/32" cable around the 1/4" rod. I used seven long pieces (9") and four short pieces (4", to help get the bottom of the cylinder). I used J-B Weld throughout the process, and whipped it all together with the 24 gauge wire at two points. There is less than $10 of material in this whip.

It fits in the 1/2" opening no problem. I may have been able to use the SS cable ties after all, or been able to use 1/8" cable with the whip knot method. However, I wouldn't have been able to get as many 1/8" cable pieces around the 1/4" rod as I was able to fit using 3/32" cable. I can see that a tube to help start the whip cables into the neck would be handy, especially once the cables get frayed.

Now I just need to let the J-B cure and get a tube to attach to my air nozzle to blow the dust out, and I'll be ready to whip it, whip it good.

Last edited:

Similar threads

- Replies

- 0

- Views

- 179

- Replies

- 8

- Views

- 664