phgachoud

Registered

Bought a coltri MCH6. Air filter was changed 1 year ago and used for a few minutes only. On the first fill of my tanks the air was wierd. Am waiting for a replacement cartidge, but takes it time to get here in south america  .

.

Filling my tanks and specially after when turning off the compressor, I saw some fumes getting out of the intake tube (I put 2m higher with a plastic tube not as the pictures you are about to see...).

I was worried that those fumes go into my tanks and of course my lungs as much. Dove my tanks for more than 1h30 in the water and didnt get dizzy so looks like am not dead and working ok. I know I should analyze my air, but its not easy to get that kind of services out here...

and working ok. I know I should analyze my air, but its not easy to get that kind of services out here...

Seing those fumes after stopping the compressor each time, I was wondering about the compressor construction and what are the lubricating oil specifications making that there is some oil going into the air the compressor absorbs, and then probably and hopefully is filtered by the filter before going into the tanks and lungs... which makes me also think of course of filter saturation level of those.

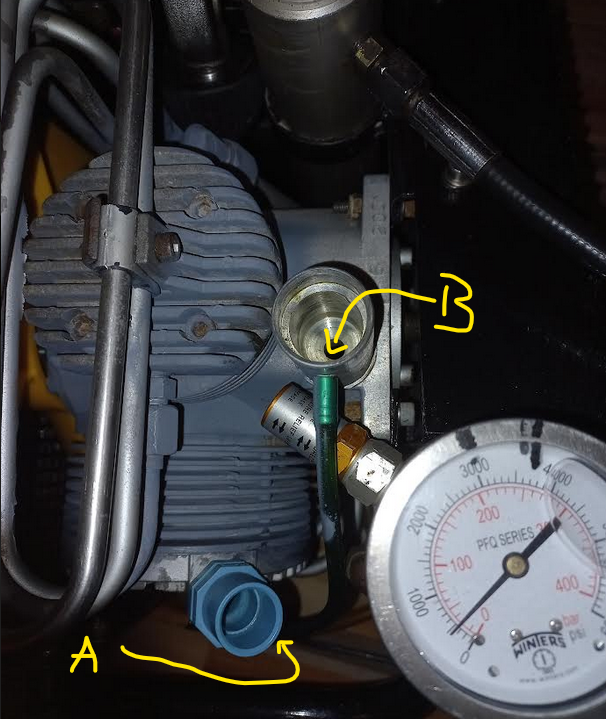

So, my understanding is that in the img above (removed the oil cap/gauge) the green tube between B and A is meant for the differences of pressure caused by the movements of the pistons to let some air interchange outside the motor, which is also the case in thermic motors (dont have the technical word for that in english). That makes sense for me in a mechanical manner, but! what about the oil getting out of it getting drained direcly into the inlet of the first piston making the oil and fumes mix with my breathing gas!!! Making me think that the oil is special enough to be not that bad in terms of healthyness or is the after compression filter guarantying that? and to what extend, knowing my current filter is probably more than 1 year old and the active carbon might be less efficient or dead.

So the big Q is, is a breathing compressor oil that special its breathable even after having been mixed with air and sometimes heated!?

For more illustration, here is where the green tube goes into the first piston through the air inlet (removed for the picture so you can see where it goes). Air comes from the blue tube, green tube's oil finishes into C as well as the tube

Thx guys!

Filling my tanks and specially after when turning off the compressor, I saw some fumes getting out of the intake tube (I put 2m higher with a plastic tube not as the pictures you are about to see...).

I was worried that those fumes go into my tanks and of course my lungs as much. Dove my tanks for more than 1h30 in the water and didnt get dizzy so looks like am not dead

Seing those fumes after stopping the compressor each time, I was wondering about the compressor construction and what are the lubricating oil specifications making that there is some oil going into the air the compressor absorbs, and then probably and hopefully is filtered by the filter before going into the tanks and lungs... which makes me also think of course of filter saturation level of those.

So, my understanding is that in the img above (removed the oil cap/gauge) the green tube between B and A is meant for the differences of pressure caused by the movements of the pistons to let some air interchange outside the motor, which is also the case in thermic motors (dont have the technical word for that in english). That makes sense for me in a mechanical manner, but! what about the oil getting out of it getting drained direcly into the inlet of the first piston making the oil and fumes mix with my breathing gas!!! Making me think that the oil is special enough to be not that bad in terms of healthyness or is the after compression filter guarantying that? and to what extend, knowing my current filter is probably more than 1 year old and the active carbon might be less efficient or dead.

So the big Q is, is a breathing compressor oil that special its breathable even after having been mixed with air and sometimes heated!?

For more illustration, here is where the green tube goes into the first piston through the air inlet (removed for the picture so you can see where it goes). Air comes from the blue tube, green tube's oil finishes into C as well as the tube

Thx guys!