I think it's a tradition to evaluate the thrust in pounds but we can convert

lb into kilogram

Trolling motors have the standard thrust step: 18 lb (8 kg), 24 lb (10 kg), 30 lb (13 kg), etc.

I've got the smallest (cheapest

) motor 18 lb or 8 kilogram of thrust, like in a children toy scooter. It's... slowly

I recommend to buy 30 lb or more.

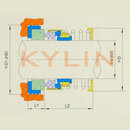

About ceramic... Trolling motor shaft tighten by 2 o-rings only and can leak on xx meters depth, cause it not for diving. You can increase its depth by ceramic seal. Most of motors have a place on the housing to mount mechanical shaft seal).

Ceramic has very big hardness, 2 hight polished ceramic washers placed face to face and pushed with hight pressure can rotate without abrasion and will never wear out. These 2 hight polished ceramic washers will seal your shaft up to 5-15 bar (depend on supplier).

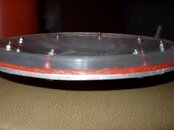

View attachment 136040