WARNING:

The strobe, like all flashtube based strobes, uses a very large capacitor to store high voltage to power the strobe. THIS VOLTAGE CAN INJURE OR KILL YOU! Ensure the strobe is not powered on and has not been powered on recently, and do not touch any wires until you verify voltages with a multimeter.

Opening will also certainly void any warranty you may have, and you may damage the strobe or cause a leak that destroys it.

OPEN ONLY AT YOUR OWN RISK!

I purchased a TG-6, ikelite case, and dual DS-51 strobes used. When I received it, I tested the camera and at least one strobe, but I don’t think I tested both strobes.

My GF got OW certified Sunday. Plan was if all went well, after she was certified I’d go on a dive with her. I wanted to take my new to me camera so on Saturday I pull it out to charge and give it a test.

Unfortunately I found that one strobe did not work. No whine of the charging cap, no ready light. I checked batteries and contacts and all looked good.

I could sent it to ikelite for repair, but then I wouldn’t have it. After some searching, I found instructions on WetPixel for opening.

Short instructions:

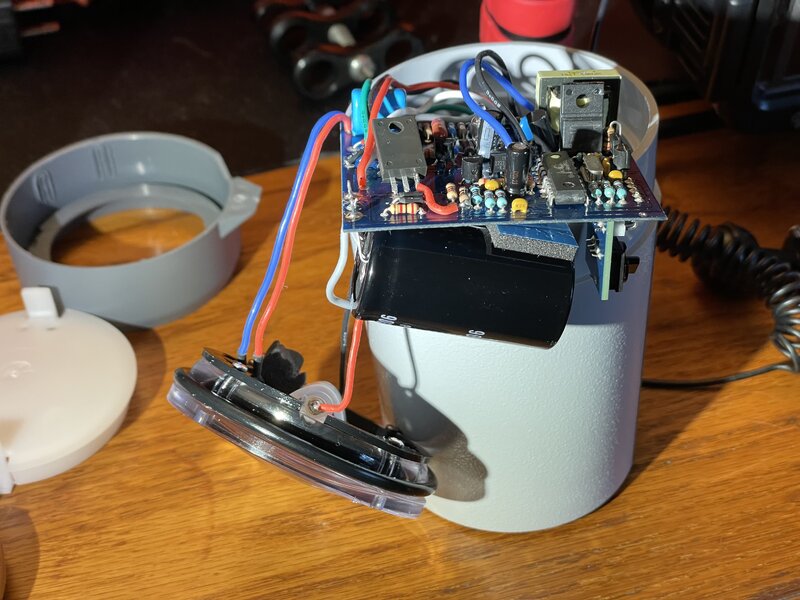

Once the strobe is pulled out of the housing, with some careful manipulation of wires the PCB can be pulled out without disconnecting wires to the battery compartment or to the ready light on the bottle of the housing.

Before pulling out, I verified that the PCB was getting voltage from the battery. I checked the voltage on the capacitor to verify it was discharged and made sure it was off before pulling out the PCB.

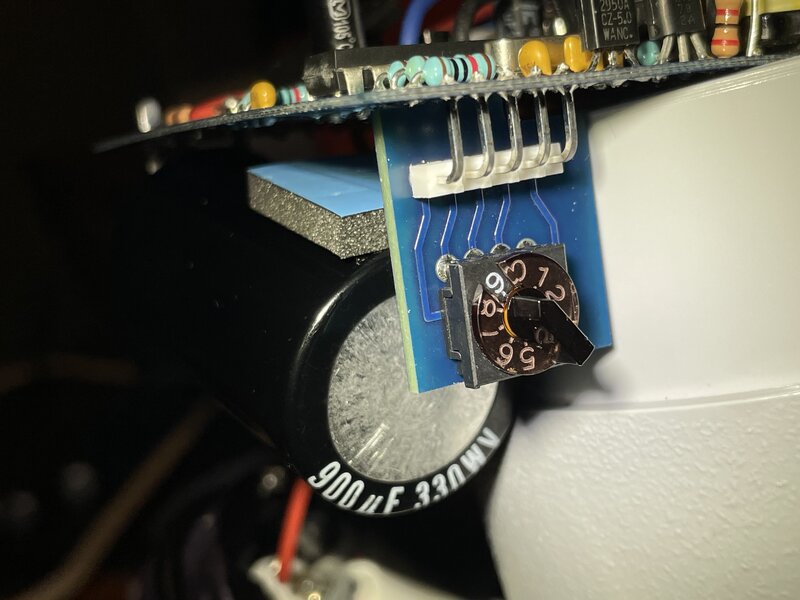

On the side of the PCB facing the back of the housing, there is a small switch on a small PCB attached to the main PCB. With the batteries in, I CAREFULLY flipped this switch once notch clockwise, from “OFF” to “TTL”. There immediately was a whine as the strobe began charging.

I turned the strobe back off, and waited for the capacitor to discharge to a safe voltage (checked with DMM) before putting the PCB back into the housing.

I inspected the housing. The knob on the back has a part with a slot inside the housing, that this small switch slots into. I figured what happened is during shipment an impact caused the PCB to slide forward in the housing (it’s mostly just friction fit), causing the switch to loose contact with the knob.

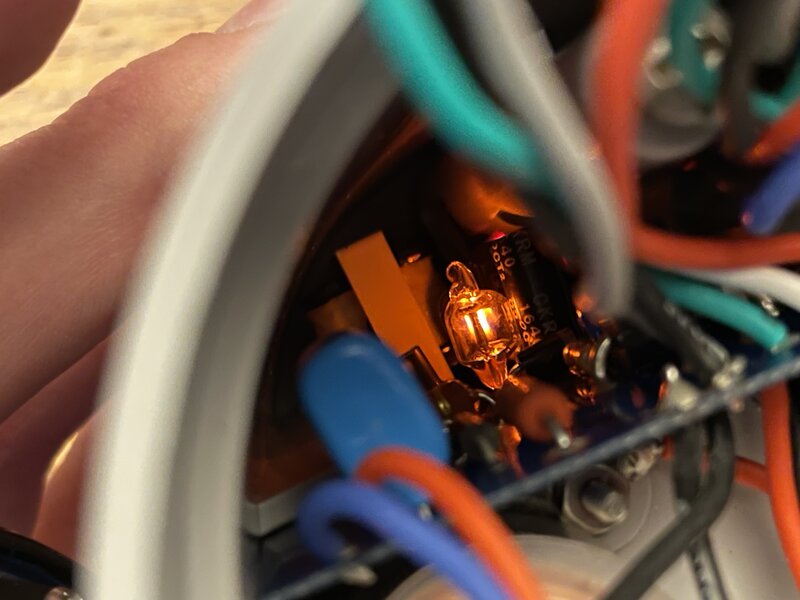

I pressed the PCB down all the way, then powered up the strobe. Again it charged up just fine. The capacitor charged to 291 volts, and a neon light on the PCB lit up. Note this neon light isn’t the ready light (that’s an LED) but rather probably an integral part of the simple charge boost circuit for the strobe.

I fired the strobe a few times, then powered it down. After waiting for the voltage on the capacitor to drop to safe levels (measured with a DMM), I then ensured the o-ring was clean, the housing the o-ring slides into was clean, applied some silicone grease, and slid the strobe back into the housing. I needed to put the o-ring into the housing before sliding in the strobe, trying to put the strobe in with the o-ring on the strobe portion caused the o-ring to pop out. While holding it in, I again used a tool to rotate it counterclockwise until it was level with the ball mount on the bottom. I put the bezel and ball mount back in and the reassembly was complete!

Result: One freshly repaired, working strobe!

The strobe, like all flashtube based strobes, uses a very large capacitor to store high voltage to power the strobe. THIS VOLTAGE CAN INJURE OR KILL YOU! Ensure the strobe is not powered on and has not been powered on recently, and do not touch any wires until you verify voltages with a multimeter.

Opening will also certainly void any warranty you may have, and you may damage the strobe or cause a leak that destroys it.

OPEN ONLY AT YOUR OWN RISK!

I purchased a TG-6, ikelite case, and dual DS-51 strobes used. When I received it, I tested the camera and at least one strobe, but I don’t think I tested both strobes.

My GF got OW certified Sunday. Plan was if all went well, after she was certified I’d go on a dive with her. I wanted to take my new to me camera so on Saturday I pull it out to charge and give it a test.

Unfortunately I found that one strobe did not work. No whine of the charging cap, no ready light. I checked batteries and contacts and all looked good.

I could sent it to ikelite for repair, but then I wouldn’t have it. After some searching, I found instructions on WetPixel for opening.

Short instructions:

- Remove screw holding ball mount from strobe.

- Pull off bezel on front of strobe.

- Four holes are in clear plastic at front of strobe. You need some sort of tool to stick in holes to rotate the strobe part by about 10° clockwise.

- Place strobe with battery door and connector sealed, face up, in a container of water around 140 °F for a bit (like 5-10 minutes).

- Air pressure in strobe will push the now-unlocked strobe front up.

- Push down on once side with a finger, the other side will be lifted slightly. Should now have room to stick a small screwdriver in and carefully pry up.

- Pull out the strobe.

Once the strobe is pulled out of the housing, with some careful manipulation of wires the PCB can be pulled out without disconnecting wires to the battery compartment or to the ready light on the bottle of the housing.

Before pulling out, I verified that the PCB was getting voltage from the battery. I checked the voltage on the capacitor to verify it was discharged and made sure it was off before pulling out the PCB.

On the side of the PCB facing the back of the housing, there is a small switch on a small PCB attached to the main PCB. With the batteries in, I CAREFULLY flipped this switch once notch clockwise, from “OFF” to “TTL”. There immediately was a whine as the strobe began charging.

I turned the strobe back off, and waited for the capacitor to discharge to a safe voltage (checked with DMM) before putting the PCB back into the housing.

I inspected the housing. The knob on the back has a part with a slot inside the housing, that this small switch slots into. I figured what happened is during shipment an impact caused the PCB to slide forward in the housing (it’s mostly just friction fit), causing the switch to loose contact with the knob.

I pressed the PCB down all the way, then powered up the strobe. Again it charged up just fine. The capacitor charged to 291 volts, and a neon light on the PCB lit up. Note this neon light isn’t the ready light (that’s an LED) but rather probably an integral part of the simple charge boost circuit for the strobe.

I fired the strobe a few times, then powered it down. After waiting for the voltage on the capacitor to drop to safe levels (measured with a DMM), I then ensured the o-ring was clean, the housing the o-ring slides into was clean, applied some silicone grease, and slid the strobe back into the housing. I needed to put the o-ring into the housing before sliding in the strobe, trying to put the strobe in with the o-ring on the strobe portion caused the o-ring to pop out. While holding it in, I again used a tool to rotate it counterclockwise until it was level with the ball mount on the bottom. I put the bezel and ball mount back in and the reassembly was complete!

Result: One freshly repaired, working strobe!