gcarter

Contributor

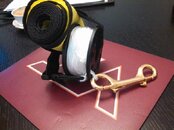

I had this happen twice, off the same boat, on the same day. Turned out the new double ender that was attaching it to me had a weak spring on one end and the jolt of entry was enough to pop it open. After replacing the bolt snap I have had no further issues.