Purely for the fun and challenge of it I used plans found on ScubaBoard to make my own aluminum backplate. Then to use the backplate I also manufactured my own wing from scratch. This rig has been dive tested. The backplate/harness and prototype wing in the pool, and then the completed rig in Lake Tahoe on 2 dives. It performed flawlessly, with only one small change I want to make. That change it to route the lower right hand OPV dump string through on of my d-rings to make it easier to find/reach. I used a plain elbow, rather than a pull-dump, on the power assembly strictly for cost reasons. Eventually that will get changed. If I ever manufacture a larger capacity wing I will use heat-sealable nylon for my bladder. I have looked inside several brand new wings and that is what they are use for the bladder.

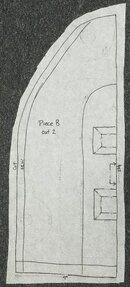

Materials and tools are common and should be available to most DIYers. I have made a PowerPoint for the backplate, and one for the wing construction. These explain and have pictures of each step, and include patterns. I haven't figured out how to attach them (they are currently too large) to this post. You can PM me and I'll email them to you. Cost for the whole project using NEW material (with the exception of the backplate aluminum) was under $140. Most of that was for the commercially made power inflator assembly and OPV.

I have confidence in the wing bladder. It is the same construction as the whitewater cataraft tubes I have been running on class 3 whitewater for the last five seasons.

Materials and tools are common and should be available to most DIYers. I have made a PowerPoint for the backplate, and one for the wing construction. These explain and have pictures of each step, and include patterns. I haven't figured out how to attach them (they are currently too large) to this post. You can PM me and I'll email them to you. Cost for the whole project using NEW material (with the exception of the backplate aluminum) was under $140. Most of that was for the commercially made power inflator assembly and OPV.

I have confidence in the wing bladder. It is the same construction as the whitewater cataraft tubes I have been running on class 3 whitewater for the last five seasons.

Attachments

Last edited: