Reefer

Registered

Recently brought a nice MK7 from ebay.

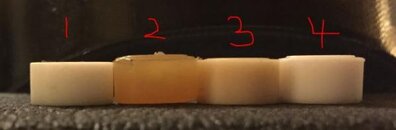

Initial test with 800 psi tank showed 153psi IP. All internal parts looked great except a piston where grease are mixed with green rusts. Surprisingly there was no shim for spring. Had hard time to take HP seat out from retainer. had no luck with forcing with air pressure from back side of retainer so used drill bit to take it carefully out. I was not sure if HP seat was glued.

So I cleaned, changed all o-rings and HP seat with a service kit from VDH and tested with tank with 800 psi. All looked great but IP was a bit high around 130 with one shim that I put between Spring and main housing. I just wanted to have a shim there.

Yesterday I tested that MK7 with 2800 psi tank. looked good with 135 IP until I depressed purge on 2nd, I heard bang! and there was air shooting through holes on HP retainer mainly one in center and had to close main valve to stop that.

I didn't thight HP seat retiner with a tool, just with my hand as much as I could, like a couple of other 1st I serviced. A HP seat retainer tool I made is very small one like one from Herman so there is not much leverage.

Will try to tight retainer tonight but are there any other things I have to take a look?

Initial test with 800 psi tank showed 153psi IP. All internal parts looked great except a piston where grease are mixed with green rusts. Surprisingly there was no shim for spring. Had hard time to take HP seat out from retainer. had no luck with forcing with air pressure from back side of retainer so used drill bit to take it carefully out. I was not sure if HP seat was glued.

So I cleaned, changed all o-rings and HP seat with a service kit from VDH and tested with tank with 800 psi. All looked great but IP was a bit high around 130 with one shim that I put between Spring and main housing. I just wanted to have a shim there.

Yesterday I tested that MK7 with 2800 psi tank. looked good with 135 IP until I depressed purge on 2nd, I heard bang! and there was air shooting through holes on HP retainer mainly one in center and had to close main valve to stop that.

I didn't thight HP seat retiner with a tool, just with my hand as much as I could, like a couple of other 1st I serviced. A HP seat retainer tool I made is very small one like one from Herman so there is not much leverage.

Will try to tight retainer tonight but are there any other things I have to take a look?