Boarderguy

Chief Narctopus Wrangler

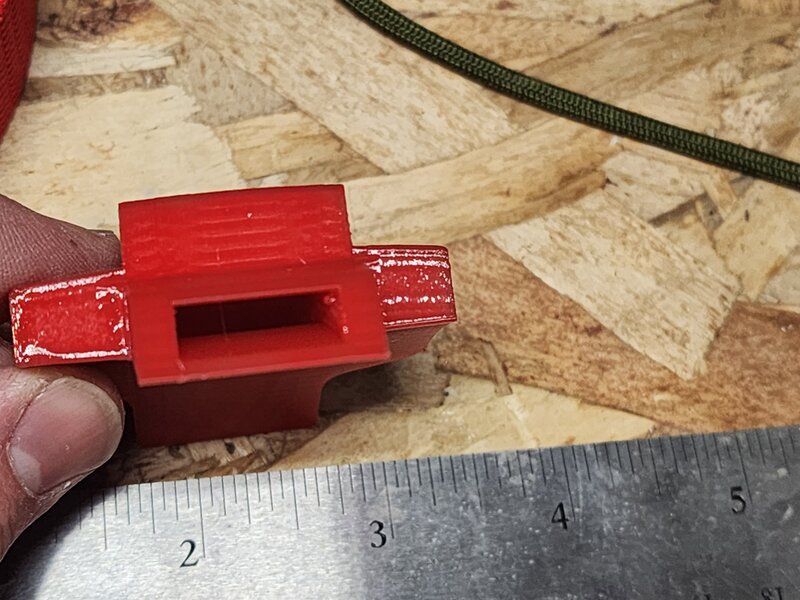

Does anyone have an STL that they would share for go pro mount on a black tip? I bought one but now have access to a 3D printer at work and don't want to pay $30 for more of them. Something similar to this pic. I'm also looking for the male side that I can attach a light to quick disconnect for changing the battery. I'm new to 3D CAD but am a quick learner so I may be able to modify if it isn't exactly what I'm looking for. Really just hoping to get something to work with that's close.