beachnik

Contributor

Has anyone had any actual experience & success solving a similar problem?

- - - -

First of all, I’ve rebuilt these things before, without problem.

Not that it would matter, but I’m disassembling the ’T’ shaped Aqua Lung Titan 1st – the model introduced in 2010.

I don’t use compressed air to blow out the diaphragm, and even if I tried, this thing would not budge - it is stuck like glue.

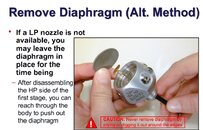

The technique I normally use is one described by Aqua Lung as the 'alternate diaphragm removal method':

-I remove the standard pin that goes thru the orifice and into the Pin Support.

-Next I insert a pin tool thru the orifice and then into the pin support.

-I press on the pin support, the diaphragm flexes - and ‘normally’ - the diaphragm pops off, but not today. It's flexing plenty, just stuck at the shoulder where is forms an air tight seal with the body.

I’ve also tried:

-soaking in water to see if the diaphragm would loosen up.

-soaking in a mixture of water and white vinegar (over night)

-put it in my ultrasonic cleaner (water and a little vinegar)

-used my painter’s Heat Gun to warm up the body and diaphragm

-Gunk Penetrating Oil

...none of this worked.

Things I haven’t tried:

-Use an Xacto knife to put a slice into the diaphragm adjacent to the ‘pin support’ - then needle nose pliers to grab/pull the diaphragm out. It’ll require a lot of force and I can just see me accidentally wacking the internal threads on the valve body, which is why I haven't tried it.

Has anyone had any actual experience & success solving a similar problem?

- - - -

First of all, I’ve rebuilt these things before, without problem.

Not that it would matter, but I’m disassembling the ’T’ shaped Aqua Lung Titan 1st – the model introduced in 2010.

I don’t use compressed air to blow out the diaphragm, and even if I tried, this thing would not budge - it is stuck like glue.

The technique I normally use is one described by Aqua Lung as the 'alternate diaphragm removal method':

-I remove the standard pin that goes thru the orifice and into the Pin Support.

-Next I insert a pin tool thru the orifice and then into the pin support.

-I press on the pin support, the diaphragm flexes - and ‘normally’ - the diaphragm pops off, but not today. It's flexing plenty, just stuck at the shoulder where is forms an air tight seal with the body.

I’ve also tried:

-soaking in water to see if the diaphragm would loosen up.

-soaking in a mixture of water and white vinegar (over night)

-put it in my ultrasonic cleaner (water and a little vinegar)

-used my painter’s Heat Gun to warm up the body and diaphragm

-Gunk Penetrating Oil

...none of this worked.

Things I haven’t tried:

-Use an Xacto knife to put a slice into the diaphragm adjacent to the ‘pin support’ - then needle nose pliers to grab/pull the diaphragm out. It’ll require a lot of force and I can just see me accidentally wacking the internal threads on the valve body, which is why I haven't tried it.

Has anyone had any actual experience & success solving a similar problem?