Frogman82

Contributor

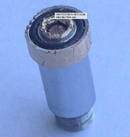

Sorry, it was scuba service tools I bought mine from. Here is a youtube link to the one I haveAh so that's what's with the ball. I think that is mandatory from a note I saw on silentexplorers.com so really hoping that is what I'll find inside.

I'd not be going above 80% though and if I do it's likely a different regulator I'll use for the stage.

It's only for under 40% O2.

Can you tell me which of the special tools from scuba clinic tools you're refering to? Might be of interest! Thanks.

Poseidon 2. stage tool

I specifically asked Poseidon about the ball, and they said it´s only recommended to replace it if the reg sees high O2, or if it is damaged. If it is a steel one and it is in good condition, it is ok to use it if you only dive air or standard 32%ish nitrox mixes.