Ojai Diver

Contributor

Agreed, it may not be worth adjusting, but I am interested in everybody's thoughts on this.

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

Everything you've read above is correct. Each of the posters has a point. Nonetheless, I understand your desire to eke just "a little more performance" out of your expensive toy. Search SB for threads on "Case Geometry Fault" and you'll learn why folks are advising you against what you are trying to do. Nonetheless, you can indeed tune the A700 down as low as 0.7" or even a bit lower, with a new seat. What that means in practice, however, is that it will perform that nicely (and easy breathers are indeed a pleasure to dive) in only ONE position: standard 45 degree face down diving position. If you look straight down, the exhalation valve will be higher than 0.7" above the middle of the diaphragm, and the reg will begin to gently freeflow. As another poster mentioned, this is a cold water hazard. But try it out, if you're a warm water diver! It'll be fun. And you can always tune it back. The case geometry fault is smaller with the A700 than with the G250/260 series, because the case is smaller. But with this shape reg (as opposed to regs like Poseidons and Hollis 500e's with coaxial diaphragm and exhaust valve), there's a physical limit to how lightly you can have the seat rest on the orifice, before differential water pressure between the diaphragm and the exhaust valve takes over and causes the valve to open (freeflow). Oh! Did I forget to say SCUBAPRO D-400??!!

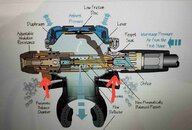

Tuning is indeed sort of done from both ends of the barrel (see pic):

View attachment 460204

The lever height and general pressure on the seat is governed by how far in you screw the orifice (on the right side of this pic). That would NOT be where I'd start this adventure. ASSUMING your shop has correctly tuned the reg in the first place, sealing pressure on the seat and lever height have already been set correctly. Therefore, as you were told by your tech, adjusting your cracking effort alone, will be accomplished by counterclockwise screwing of the microadjust screw inside the knob.

Pry the little label off the knob, and unscrew the set screw inside the knob so you can pull it off. PAY ATTENTION to how gently that screw was set. When you replace your knob, you do not want to overtorque that screw. It's ONLY to hold the knob on. PM me if you want me to send you a replacement decal after you're done.

Once the knob is off, using a small flat-bladed screwdriver (3-4mm), start to unscrew the micro adjust while your reg is in the sink and pressurized. Hold the reg with the diaphragm parallel to the water and with the mouthpiece straight up. Then find and mark with a piece of tape the point at which the water level in the sink causes the second stage to JUST BEGIN to hiss. Then (assuming that's 1.1" of cracking effort) hold the reg with your tape mark 0.2" higher. Unscrew the microadjust until the reg JUST BEGINS to hiss. Bingo, you're done. Now tuned to 0.9" of water. Replace the knob, dry everything off perfectly and stick a new decal back on.

A700 Service Technician

Don't sweat the tank pressure. The Mk11 is just a non-environmentally sealed Mk17. Great reg! Should shift IP upwards around 8psi max, from full tank to empty. But it doesn't matter. Your balanced second stage doesn't care about +/- 8 psi. Heck, it doesn't care much about -50 psi! You can breath that reg on an empty tank and won't see it pull hard until tank is around 200 psi, depending upon depth. At that point, you're OOA, and without warning, if you haven't watched your gauges.

The tech said he set my IP on the high side (he did not give me a number) but from the above it sounds like that is not a concern in making this adjustment, unless it was creeping up, correct?

Thanks again!