halocline

Contributor

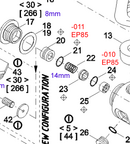

You might as well disassemble the MK25, pull the piston out, then as Zung said you can push out the o-ring and bushings, replace the o-ring and hope it fixes it. You could get the installation tool, or you can try the old way of putting everything in place without the piston, including the seat assembly, then the idea is that the seat and spring hold the bushings and o-ring in place while you install the piston. I've done that in a pinch on a few MK20s with success in the past, but I wouldn't recommend it as a general practice. The bushing installation tool is pretty useful if you can find one. Or, you can try Zung's approach of putting the piston in place and then pushing the bushings and o-ring over the piston shaft, then install the seat retainer.

Something's not installed correctly, or was damaged in installation, that's the only reason I think of for an actual leak at the HP o-ring. The common problem is the squeal/honk during breathing, but no leak; that's a kind of resonance with the piston/main spring that's not dampened by sufficient lube.

Unless you want to go back to the tech, tell him to try again.

Something's not installed correctly, or was damaged in installation, that's the only reason I think of for an actual leak at the HP o-ring. The common problem is the squeal/honk during breathing, but no leak; that's a kind of resonance with the piston/main spring that's not dampened by sufficient lube.

Unless you want to go back to the tech, tell him to try again.