A couple of points. A tank can be filled in 5-7 minutes but it shiuldn't be. It gets way too hot and stresses the tank.

And many compressors only use vegetable oil. There is nothing inappropriate about that.

Show me one compressor company which recommends a vegetable oil (i.e sunflower, canola, rapeseed oil) be used in a high pressure breathing air compressor.

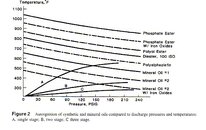

In the past a mineral oil was the oil of choice, but today all the major manufacturers have switched to ester or polyalphaolefin (PAO) synthetics.

Bauer USA loads its compressors with Ultrachem Chemlube 800 a trimelliate ester, Bauer Germany loads its new compressors with a trimellitate ester from Shell. Coltri Europe uses a diester Alusynt CE750, and Nuvair (Coltri USA) uses either a diester from Ultrachem (Chemlube 751) or a PAO Omnilube 455 from Ultrachem.

The switch from mineral to synthetic oils was due to improved thermal and oxidative resistance, a very important improvement in flash point and auto-ignition point plus a decrease in the toxicity of the volatile vapors which come off the oil when heated which are adsorbed on the activated charcoal bed but present a risk to the diver if released back into the compressed breathing air.

There are no vegetable oils used in the industry and the only time I have come across a vegetable oil used in a compressor two divers died from CO poisoning at a Mexican fill station. Vegetable oils have poor flash points and thermal resistance.

I have seen automobile oils which consist of about 30 percent toxic additives used in scuba high pressure compressors on the island of Roatan.

If one sees a vegetable or automobile oil being used in a breathing air compressor please walk away.

---------- Post added December 13th, 2012 at 09:57 PM ----------

After watching the video I was struck by the lack of evidence continuity....I would be very surprised if this was any video from an official investigation.

It certainly would not be acceptable in any North American court - criminal or civil.

Don't know if it would be accepted in Mexico...rather doubt it.

Take a trip to Mexico sometime and this would be par for the course. Often no chain of custody and tampering of evidence has happened with previous fatalities.

This one looks like they may have learned from previous mistakes such as not having a CO analyzer available.