As an alternative to welding the end, simply cut a slot in the end of the SS rod, either with a cutting wheel in a grinder, or use a hacksaw. Then center the cable in the slot, and bang the slot closed with a hammer.I like that! I have one of those tank-caps available. I don't have access to a welder (or welder-skills) unfortunately. Though I have been thinking lately, it might be useful to take a metal-working class at some point.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

SlugLife

Contributor

I like that idea. The steel rod just arrived in the mail, and I managed to cut about 1.25 inches before my Dremel got very hot. The steel cable is supposed to arrive later today. Once I have the cable I'll see if I need to cut any more or not. (this is a 0.25 in x 36 inch rod if anyone is following along). I'll probably also grind some flat-spots along the top edge, to give the drill better grip.As an alternative to welding the end, simply cut a slot in the end of the SS rod, either with a cutting wheel in a grinder, or use a hacksaw. Then center the cable in the slot, and bang the slot closed with a hammer.

I doubt anyone should need a rod any thicker, unless you go with another material like aluminum. or a wooden dowel. A longer rod would also be fine, I just wanted this to be a little easier to store.

edit: I ground the other end into a "hex" (6-sided) shape. It doesn't have to be "perfect" just good enough for the drill to grip onto.

If you find the slot in the 1/4" rod doesn't hammer down over the cable well enough, the a bit of epoxy should work.I like that idea. The steel rod just arrived in the mail, and I managed to cut about 1.25 inches before my Dremel got very hot. The steel cable is supposed to arrive later today. Once I have the cable I'll see if I need to cut any more or not. (this is a 0.25 in x 36 inch rod if anyone is following along). I'll probably also grind some flat-spots along the top edge, to give the drill better grip.

I doubt anyone should need a rod any thicker, unless you go with another material like aluminum. or a wooden dowel. A longer rod would also be fine, I just wanted this to be a little easier to store.

View attachment 801570

edit: I ground the other end into a "hex" (6-sided) shape. It doesn't have to be "perfect" just good enough for the drill to grip onto.

View attachment 801590

Wrapping the slit end with some the the cable, or even good braided line, and then epoxy would also help.If you find the slot in the 1/4" rod doesn't hammer down over the cable well enough, the a bit of epoxy should work.

Gone for diving

Contributor

3/4 SPT is the most common in dive tanks. (Sometimes referred to mechanical straight pipe)I suppose the one thing I can't tell, is if the PVC it's 3/4-14 based on the description (they all just say 3/4). I might drag one of my empty 6cu bottles to a hardware store to be sure.

Same a 3/4 npt, just doesn't have a taper to the theads,

Note 3/4 npt etc measures closer to 1inch

SlugLife

Contributor

How long do you think I should make the stainless-steel strands? I could do 7.5 to 8 inches (tank is 7in about), slightly larger than the tank diameter. Or a few inches more, to have the sides of the cable scrape along the inside.

Boarderguy

Chief Narctopus Wrangler

Think weed eater string... they will flex a bit while being spun around at drill speed.How long do you think I should make the stainless-steel strands? I could do 7.5 to 8 inches (tank is 7in about), slightly larger than the tank diameter. Or a few inches more, to have the sides of the cable scrape along the inside.

SlugLife

Contributor

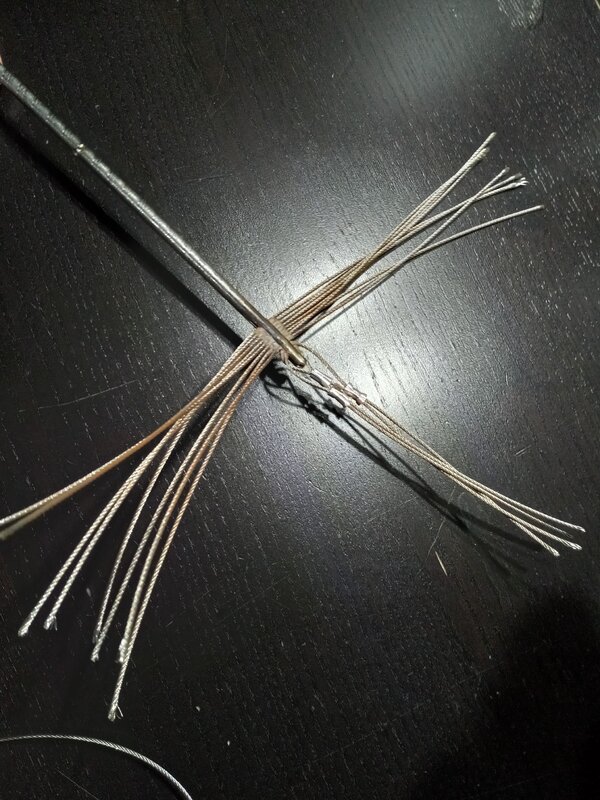

I'll do a proper DIY writeup later, but here's what I have so far (pics below)

A few quick notes:

A few quick notes:

- I think 12-inches (6-inch radius) is about right for the strands.

- To secure the strands, a hammer didn't work. However, a table-vice-grip worked just fine. I also put a little bit of super-glue in the middle, which may or may-not be doing anything.

- I suspect fewer strands might be better. Fewer strands would be a little more flexible, and be easier to insert and remove in the tank-neck.

- To get the bottom of the tank, I pointed a couple strands downward using aluminum crimps that commonly ship with stainless-steel wire.

- 36-inch steel rod is honestly too long, it wobbles a little (but that's probably because I slightly bent it). I'll probably cut it closer to 24-inches.

- (not recommended) I didn't use the PVC thread protector yet. I got impatient and wanted to try it. So, I use some masking tape, and some pex pipe I had sitting around to protect the threads. I'm going to do it properly later, but I wanted to give it a quick try.

- I think it worked. It's currently hard to see through a fine cloud of rust in the tank, and I haven't washed out the tank yet, so the rust dust will be evenly distributed along the sides. I could blow it out but didn't feel like setting that up just yet.

- I'm thinking I may just take these tanks to hydro (8 months left, but I have 4 other thanks that need hydro, and might as well save a trip), and then do another whip (if needed) and wash then with water and a rust inhibitor and dry as quickly as possible.

SlugLife

Contributor

I ended up buying one of these at a local hardware store in the middle of nowhere, with tax, it was $1.72. It threads perfectly, has a nice sized opening for inserting the whip, and covers 8-9 threads, which is plenty for steel.

OMyMyOHellYes

Contributor

You are going to end up being a tank geek if you don't watch it, mister.

Similar threads

- Replies

- 9

- Views

- 988

- Replies

- 54

- Views

- 4,158

- Replies

- 6

- Views

- 909