Maybe 208 as well... It's an industrial voltage.So air compressors will be rated for either 110V or 240V in the US?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coltri MCH 11, Electric or Gas driven?

- Thread starter Aris Penaranda

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Aris Penaranda

Registered

We have 220-230v single phase line to ground. 3 phase could be requested from the power company at considerable cost. This will be in the Mindoro island in a coastal village about 130 km from Puerto Galera Philippines. I really would have immediately chosen the electric models if the voltage from the grid does not drop so low in the afternoon hours. This will be my first compressor so I'm trying to minimize the trouble in the future. Thanks for the replies.

Pao

Contributor

Mindoro? Gas would definitely be your first choice. Whitetip has a shop in PG. You might consider getting your system from them so you don't have to go off island for support. Oriental or Occidental?

Aris Penaranda

Registered

To be exact, the location will be Gloria, Oriental Mindoro. I purchased 6 AL-80 from Aquaventure white tip in Puerto Galera but the compressor block/pumping unit will be sourced overseas at a lower price. Frame and motor/engine will be sourced locally. Yes the unreliable power supply got me thinking on getting a gas engine. I'm still weighting my options. And also searching for nearby areas where I could possibly get my tanks filled by others.

rcontrera

Contributor

The MCH11 is just a single phase MCH13. In the US, we offer them with either a gas engine or electric motor ... both at 5.5 horse power and they cost the same ... electric or gas. However, if you are running this inside your garage, noise can be a killer. The electric generates 81 decibels while the gas 92.

Aris Penaranda

Registered

Originally on the title it was MCH 11-13. But since my options were only single phase or gas, I deleted 13. I will find ways to isolate or minimize the noise whatever I come up with. By the way, through searching, I have gone through some of your other post here and on TDF that helped me to narrow it down to MCH-11. Thanks Ray.

Hi

I’m not going to comment on your choice type or size of compressor just to point out first a couple of considerations you may have overlooked, First your choice of a 4Kw 5.5 BHP single phase motor size is on the big size for the average domestic generator due to the starting amperage and draw. Be aware of this starting factor also using your mains single phase at 110 volt with your local 60Hz domestic supply.

Also the motor you are intending buying locally is for a USA 60 Hz supply. However 60Hz motors are mostly built on what is called a NEMA frame. Now because you are intending fitting your own 60Hz motor to an Italian Coltri you have a problem from the get go.

Be aware all European made compressors use IEC frame slots built for the European IEC frame motors. These are not the same as the 60Hz NEMA frame motors and don’t inter fit at your 4Kw size range.

More so to get the motor shaft lined up with the driven shaft on the compressor block you need to use the front slots on the compressor frame, needless to say this means that the back slots are now not lined up and you will need to drill and a new set of slots.

Added to your problems is your additional requirement to have a engine drive option included.

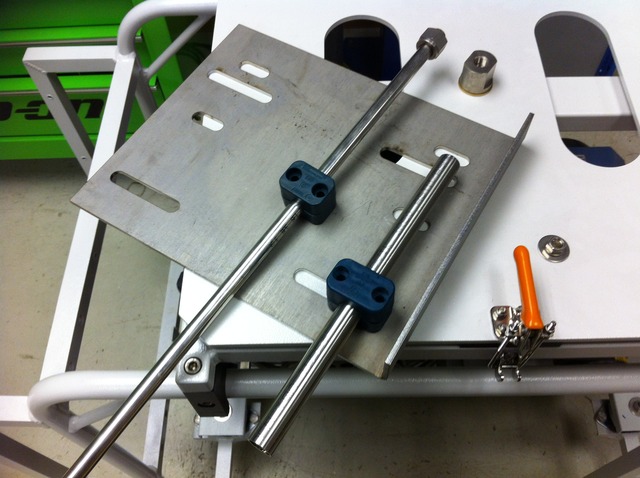

The photo enclosed shows a stainless adaptor plate for a small scuba compressor when using either a 5.5BHP 4Kw IEC motor (2 of 4 pole, 3000 or 1500 rpm) (the long slots) with the equivalent petrol engine being a 8 BHP Honda GX240 engine (3600 RPM) shown as the short slots. I could use a marker pen and draw in where the alternative NEMA frame slots for the US market fit but its not pretty hence the need for two separate motor/engine base plates for the two NEMA or IEC markets.

But the kicker in all this is that you may be reading performace and size requirement figures based on European voltage and Hz ie for single phase European 240 Volt 50 Hz single phase motor. A huge difference between this and your 110 volt 60Hz motors in starting amperage and current draw. (Hence the 2 leg or 2 drop suggestions for the US markets)

Note also your pulley and belt length will differ swapping the 4 pole motor to Honda but at 60Hz only the 2 pole 3600 rpm 60Hz motor is the same RPM as the Honda engine at full RPM

And this is just the start of your problems.

I’m not going to comment on your choice type or size of compressor just to point out first a couple of considerations you may have overlooked, First your choice of a 4Kw 5.5 BHP single phase motor size is on the big size for the average domestic generator due to the starting amperage and draw. Be aware of this starting factor also using your mains single phase at 110 volt with your local 60Hz domestic supply.

Also the motor you are intending buying locally is for a USA 60 Hz supply. However 60Hz motors are mostly built on what is called a NEMA frame. Now because you are intending fitting your own 60Hz motor to an Italian Coltri you have a problem from the get go.

Be aware all European made compressors use IEC frame slots built for the European IEC frame motors. These are not the same as the 60Hz NEMA frame motors and don’t inter fit at your 4Kw size range.

More so to get the motor shaft lined up with the driven shaft on the compressor block you need to use the front slots on the compressor frame, needless to say this means that the back slots are now not lined up and you will need to drill and a new set of slots.

Added to your problems is your additional requirement to have a engine drive option included.

The photo enclosed shows a stainless adaptor plate for a small scuba compressor when using either a 5.5BHP 4Kw IEC motor (2 of 4 pole, 3000 or 1500 rpm) (the long slots) with the equivalent petrol engine being a 8 BHP Honda GX240 engine (3600 RPM) shown as the short slots. I could use a marker pen and draw in where the alternative NEMA frame slots for the US market fit but its not pretty hence the need for two separate motor/engine base plates for the two NEMA or IEC markets.

But the kicker in all this is that you may be reading performace and size requirement figures based on European voltage and Hz ie for single phase European 240 Volt 50 Hz single phase motor. A huge difference between this and your 110 volt 60Hz motors in starting amperage and current draw. (Hence the 2 leg or 2 drop suggestions for the US markets)

Note also your pulley and belt length will differ swapping the 4 pole motor to Honda but at 60Hz only the 2 pole 3600 rpm 60Hz motor is the same RPM as the Honda engine at full RPM

And this is just the start of your problems.

Aris Penaranda

Registered

Hi Lain,

I have also seen a lot of your posts on other threads and other sites. They have been very helpful as well.

I am really contemplating now on getting a whole set vs just the block/pumping unit, either gas or electric. The LDS quoted me a price difference of US$ 1500. I think I would not have saved much if I buy it in pieces or assemble my frame. Regarding the bolting fitment, I think I can make all the modifications myself. I'm doing some more research now with emphasis on a gas driven machine due to the high power requirements that even the available power from the grid in my area might be insufficient (voltage sag). Generator is not yet on the budget. I rely on a small off-grid solar/battery set-up to provide my basic electrical needs. No heavy motors or A/C.

I have also seen a lot of your posts on other threads and other sites. They have been very helpful as well.

I am really contemplating now on getting a whole set vs just the block/pumping unit, either gas or electric. The LDS quoted me a price difference of US$ 1500. I think I would not have saved much if I buy it in pieces or assemble my frame. Regarding the bolting fitment, I think I can make all the modifications myself. I'm doing some more research now with emphasis on a gas driven machine due to the high power requirements that even the available power from the grid in my area might be insufficient (voltage sag). Generator is not yet on the budget. I rely on a small off-grid solar/battery set-up to provide my basic electrical needs. No heavy motors or A/C.

Pao

Contributor

@Aris Penaranda

Are you trying to run a small commercial operation or starting a small tour company? I did some snorkeling in the Mansalay/Bulalacao area some years ago and it looks promising.

Are you trying to run a small commercial operation or starting a small tour company? I did some snorkeling in the Mansalay/Bulalacao area some years ago and it looks promising.

From an end user perspective needing both petrol and electric oprions (provided the above post considerations are met) and the compressor frame itself is slotted for both motor and engine it is always cheaper to buy the compressor with a good quality Petrol Engine already fitted and to buy the electric motor and starter separate from an independant electrical vendor than buy it the other way around.

Coltri for example on some models sell a genuine Honda engine at the same price as their cheaper SOGA electrical motor with one caviat that for the US market the SOGA motor is fitted in a IEC frame. The motor is specially wound for 60Hz market and it's difficult to find an alternative 60Hz on a IEC frame anywhere else.

There are also a lot more electrical motor vendors and retailers than for Honda or Sabaru agents. Not withstanding additional consideration with the amount of poor quality China knock off copies to contened with. So with the buying power a compressor brand buying a pallet load of engines at a time they can make you a good deal on a petrol engine, when comparied to them having to mess around with wires and connections on/ off switches etc that a elecriacal compressor build requires.

But not all electrical motors are equal either take EFF 1 or 2 or 3 and varous starter options also. Direct on line DOL as opposed to a soft start or VFD drive can also make a huge difference in cost not always known at the time of purchase.

Running costs also need to be calculated and the short running hours of the little engine mounted 5 litre fuel tank isnt long. I could work this out later if you like for the block.

Im not a great fan of big petrol engines (10BHP) and again consideration for a small diesel engine such as the Yanmar L100 may be an option albeit much more expensive but it could be a consideration.

Another consideration (we adopted for small petrol engine builds for the US Navy SEAL teams) is fitting a small vaccum assisted fuel lift pump to the Honda engine (a small 1/8" tap into the engine block modification) and using a separate 5 US gallon (20 litre) outboard motor plastic fuel tank, with a 10 foot long bulb pump connection you can store the fuel away (or in your case) outside from the hot engine and save burning the place down when the 5 ltr fuel tank runs out and you think its a good idea to refill the tank over an already hot engine. Iain.

Coltri for example on some models sell a genuine Honda engine at the same price as their cheaper SOGA electrical motor with one caviat that for the US market the SOGA motor is fitted in a IEC frame. The motor is specially wound for 60Hz market and it's difficult to find an alternative 60Hz on a IEC frame anywhere else.

There are also a lot more electrical motor vendors and retailers than for Honda or Sabaru agents. Not withstanding additional consideration with the amount of poor quality China knock off copies to contened with. So with the buying power a compressor brand buying a pallet load of engines at a time they can make you a good deal on a petrol engine, when comparied to them having to mess around with wires and connections on/ off switches etc that a elecriacal compressor build requires.

But not all electrical motors are equal either take EFF 1 or 2 or 3 and varous starter options also. Direct on line DOL as opposed to a soft start or VFD drive can also make a huge difference in cost not always known at the time of purchase.

Running costs also need to be calculated and the short running hours of the little engine mounted 5 litre fuel tank isnt long. I could work this out later if you like for the block.

Im not a great fan of big petrol engines (10BHP) and again consideration for a small diesel engine such as the Yanmar L100 may be an option albeit much more expensive but it could be a consideration.

Another consideration (we adopted for small petrol engine builds for the US Navy SEAL teams) is fitting a small vaccum assisted fuel lift pump to the Honda engine (a small 1/8" tap into the engine block modification) and using a separate 5 US gallon (20 litre) outboard motor plastic fuel tank, with a 10 foot long bulb pump connection you can store the fuel away (or in your case) outside from the hot engine and save burning the place down when the 5 ltr fuel tank runs out and you think its a good idea to refill the tank over an already hot engine. Iain.

Similar threads

- Replies

- 17

- Views

- 1,525

- Replies

- 7

- Views

- 1,866

- Replies

- 12

- Views

- 2,117

- Replies

- 33

- Views

- 6,837

- Replies

- 25

- Views

- 5,157