aoumi

Registered

Hi,

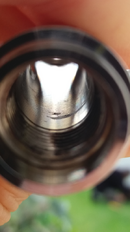

Overhauling my G250V, and have cleaned out the grease residue etc from the air barrel. But when looking down the air barrel, from the adjustment knob side, their seems to be either a rock hard build-up of gunk or maybe it's corrosion eaten into the barrel, where the o-ring of the adjustment knob is normally positioned in the balance chamber.

Unless this area of imperfection is sorted out and returned back to a smooth surface, the new o-ring on the adjustment knob, when re-installed, isn't going to make a great seal.

I have scrubbed away down there with a firm toothbrush, hot water, and dish washing liquid, but it won't move.

Holding the air barrel up to the sun at just the right angle so that the sunlight hits the area in question, it seems to be a slight green colour like corrosion, and may have eaten into the air barrel in one spot exactly where the o-ring would sit. I was unable to capture the slight green colour under sunlight.

See attached photos....

Does this mean a replacement air-barrel is required due to possible corrosion? Or just a good ride in an ultrasound (which I don't have).

Thanks

Overhauling my G250V, and have cleaned out the grease residue etc from the air barrel. But when looking down the air barrel, from the adjustment knob side, their seems to be either a rock hard build-up of gunk or maybe it's corrosion eaten into the barrel, where the o-ring of the adjustment knob is normally positioned in the balance chamber.

Unless this area of imperfection is sorted out and returned back to a smooth surface, the new o-ring on the adjustment knob, when re-installed, isn't going to make a great seal.

I have scrubbed away down there with a firm toothbrush, hot water, and dish washing liquid, but it won't move.

Holding the air barrel up to the sun at just the right angle so that the sunlight hits the area in question, it seems to be a slight green colour like corrosion, and may have eaten into the air barrel in one spot exactly where the o-ring would sit. I was unable to capture the slight green colour under sunlight.

See attached photos....

Does this mean a replacement air-barrel is required due to possible corrosion? Or just a good ride in an ultrasound (which I don't have).

Thanks

Attachments

-

Screenshot_2018-03-21-15-22-42.png386 KB · Views: 152

Screenshot_2018-03-21-15-22-42.png386 KB · Views: 152 -

Screenshot_2018-03-21-15-22-02.png321.3 KB · Views: 131

Screenshot_2018-03-21-15-22-02.png321.3 KB · Views: 131 -

Screenshot_2018-03-21-15-22-00.png396 KB · Views: 124

Screenshot_2018-03-21-15-22-00.png396 KB · Views: 124 -

Screenshot_2018-03-21-15-21-28.png367.5 KB · Views: 143

Screenshot_2018-03-21-15-21-28.png367.5 KB · Views: 143 -

Screenshot_2018-03-21-15-21-14.png329.3 KB · Views: 122

Screenshot_2018-03-21-15-21-14.png329.3 KB · Views: 122 -

Screenshot_2018-03-21-15-21-05.png403.2 KB · Views: 131

Screenshot_2018-03-21-15-21-05.png403.2 KB · Views: 131