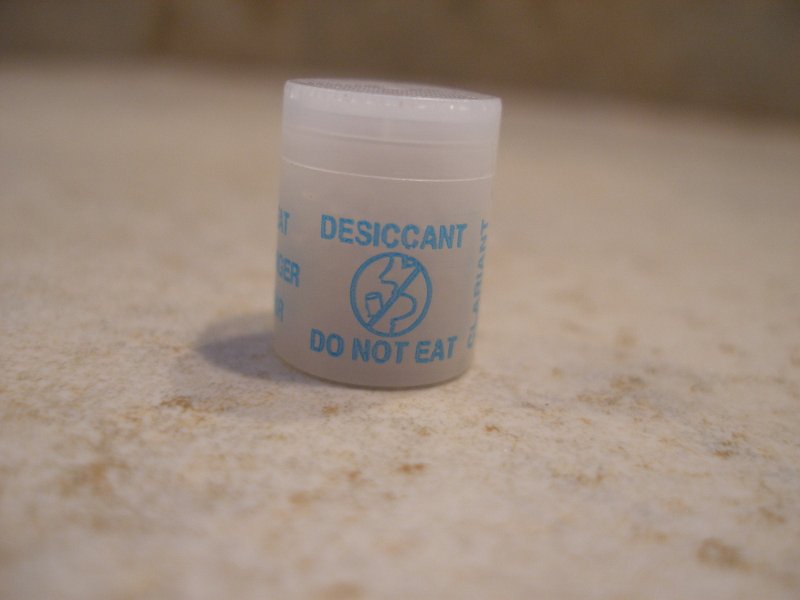

Cheap boho that I am, I wonder if one can use the plastic desiccant 'bins' one finds in vitamin bottles in one's camera housing. I already, successfully, reuse my little bagged desiccants by drying them at low heat in the oven, around 100 degrees, a temperature too low to melt t

he plastic.

he plastic.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Desiccant Question

- Thread starter Ryan B.

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

tarponchik

Contributor

Problem is, you never know, how much water this cartridge had already absorbed. Such cartridges usually lack color indicator.

the strips are nicer because you don't need to worry about dust and stuff.

The crystals kind can get crushed into smaller pieces.

tarponchik

Contributor

I recommend against 275 deg. F

Reasons:

I read that 245 deg. F (for 24h, starting at room temp.) is better, because a bit above and you may reach the melting temperature of Tyvek (if that is the material used for the baggie containing the pellets). So, the worse your oven temperature control is (the further swings around a not so well defined nominal) the more you may want to stay a little extra below the 245 deg. F. I knew I might have been a bit high when some (not all) of the little baggies turned a bit lightly brownish in areas (like at the seams where there were no pellets (mass) and evaporating moisture) and slightly wrinkly. So I staid an extra 10 degrees lower. Some day I get a small toaster oven so as to not occupy our kitchen oven for that long just at the most inopportune time... A digital toaster oven I looked at does not let you set anything below 250 deg. F - and just because it's digital does not mean it controls temperature better. I'll get a cheap one and a thermometer and go from there and then mark the dial setting...

links (hope copy and paste works, didn't read up on how to properly post links):

AN71: Desiccant Use and Regeneration (drying) | Sea-Bird Electronics

Types Of Desiccants | USA Emergency Supply

Reasons:

I read that 245 deg. F (for 24h, starting at room temp.) is better, because a bit above and you may reach the melting temperature of Tyvek (if that is the material used for the baggie containing the pellets). So, the worse your oven temperature control is (the further swings around a not so well defined nominal) the more you may want to stay a little extra below the 245 deg. F. I knew I might have been a bit high when some (not all) of the little baggies turned a bit lightly brownish in areas (like at the seams where there were no pellets (mass) and evaporating moisture) and slightly wrinkly. So I staid an extra 10 degrees lower. Some day I get a small toaster oven so as to not occupy our kitchen oven for that long just at the most inopportune time... A digital toaster oven I looked at does not let you set anything below 250 deg. F - and just because it's digital does not mean it controls temperature better. I'll get a cheap one and a thermometer and go from there and then mark the dial setting...

links (hope copy and paste works, didn't read up on how to properly post links):

AN71: Desiccant Use and Regeneration (drying) | Sea-Bird Electronics

Types Of Desiccants | USA Emergency Supply

tarponchik

Contributor

The 1st reference recommends 245 F for 24 hrs. Not surprisingly, cause lower temperature takes longer to dry. I'd say, your electricity bill will overweight whatever you save on buying new drying agent. Especially, because we are talking small loads of cartridges salvaged from vitamin bottles.

Being a scrooge myself,I'd suggest buying a pack of paper drying bags once, then regenerating them in bulk at higher temperature but shorter time.

Being a scrooge myself,I'd suggest buying a pack of paper drying bags once, then regenerating them in bulk at higher temperature but shorter time.

Similar threads

- Replies

- 2

- Views

- 343

- Replies

- 17

- Views

- 2,012