You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Cave reel

- Thread starter stevetto

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Bison Ravi

Contributor

looks pretty nice!

halocline

Contributor

great job!

lucca brassi

Contributor

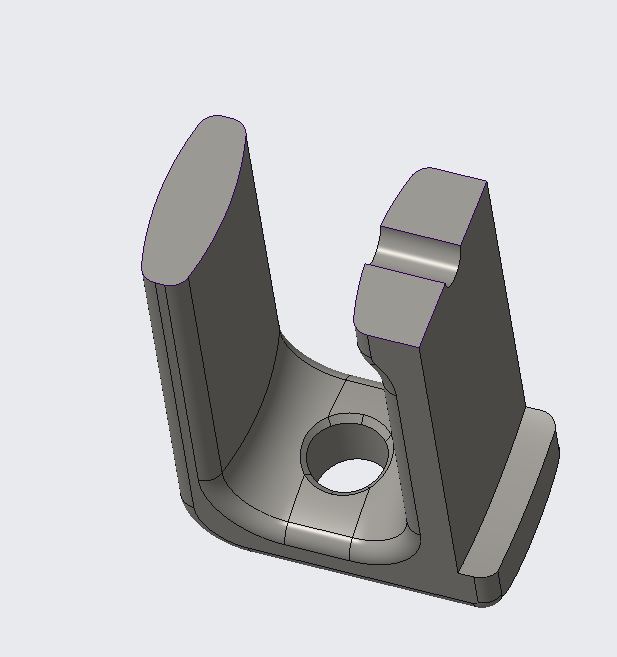

Why did you left clearance between wheel outer side and rope guide ?

Otherwise nice work !

Otherwise nice work !

Cave and wreck reels has to be as simple as possible and one of the most important things is to avoid the rope to jam.

So clearance between parts has to be smaller or much bigger than the rope diameter.

It would be possible to close the gap with an additional part or modified rope guide or make a closed frame handle, but it increase the possibility of rope jamming and makes the design more complicated. The rope guide is relative thin, you can deform it. This can increase or decrease the gap......

With this opened type handle you can change the drum easily.

And other manufacturers use the same design.

The main difference between mine and others is the handle shape.

The handle's surface is domed and rounded everywhere. It is more ergonomic than a plate used by others.

So clearance between parts has to be smaller or much bigger than the rope diameter.

It would be possible to close the gap with an additional part or modified rope guide or make a closed frame handle, but it increase the possibility of rope jamming and makes the design more complicated. The rope guide is relative thin, you can deform it. This can increase or decrease the gap......

With this opened type handle you can change the drum easily.

And other manufacturers use the same design.

The main difference between mine and others is the handle shape.

The handle's surface is domed and rounded everywhere. It is more ergonomic than a plate used by others.

Have you thought about the possibility of fusing between metals. Ie Aluminium and steel? I know it is a real PITA with my underwater housing.

Have you thought about the possibility of fusing between metals. Ie Aluminium and steel? I know it is a real PITA with my underwater housing.

If you are talking about the possibility of galvanic corrosion it is always a risk between different metals in electrolyte. And salt water is a good electrolyte.

For safety reasons and to decrease the rate of galvanic corrosion Loctite screw glue was used between different parts. Fix the screw and behaves a little bit as an insulator.

Have you thought about the possibility of fusing between metals. Ie Aluminium and steel? I know it is a real PITA with my underwater housing.

And aluminium parts are hard anodized!!

It results a much thicker oxide layer than a simple anodizing process. It is dramatically increase the corrosion resistance.

Similar threads

- Replies

- 6

- Views

- 993

- Replies

- 6

- Views

- 804

- Replies

- 15

- Views

- 2,589

- Replies

- 28

- Views

- 3,076