All of the information above is accurate. No worries.

About the SP6498 number.... SP6498 is a U.S. PHMSA special permit number to manufacture and offer for sale a "special" pressure vessel. The SP6498 number can be referenced through the Pipeline Hazardous Material Safety Administration (PHMSA) web site. For this particular special number, see link:

Hazardous Materials Special Permits Lists | PHMSA

Here you can find information about SP6498. The PHMSA web site will reference to a lot of literature about SP6498 to include an alloy composition of AA-6351. It also references a number of reports that speak to explosive ruptures of these cylinders; albeit, the rupture numbers are small quantities, ie. 13 tanks total.

The funny thing is everyone talks about 6351 as the bad alloy and everyone yammers on about "Sustained Load Cracking". I can't find any reference to SLC in the engineering databases of the American Society of Materials (formerly Metals) or the American Society of Mechanical Engineers (the design authority for pressure vessels). Funny thing, if you reference this document:

https://www.luxfercylinders.com/img...uminium_scuba_cylinders_safety_alert_2217.pdf

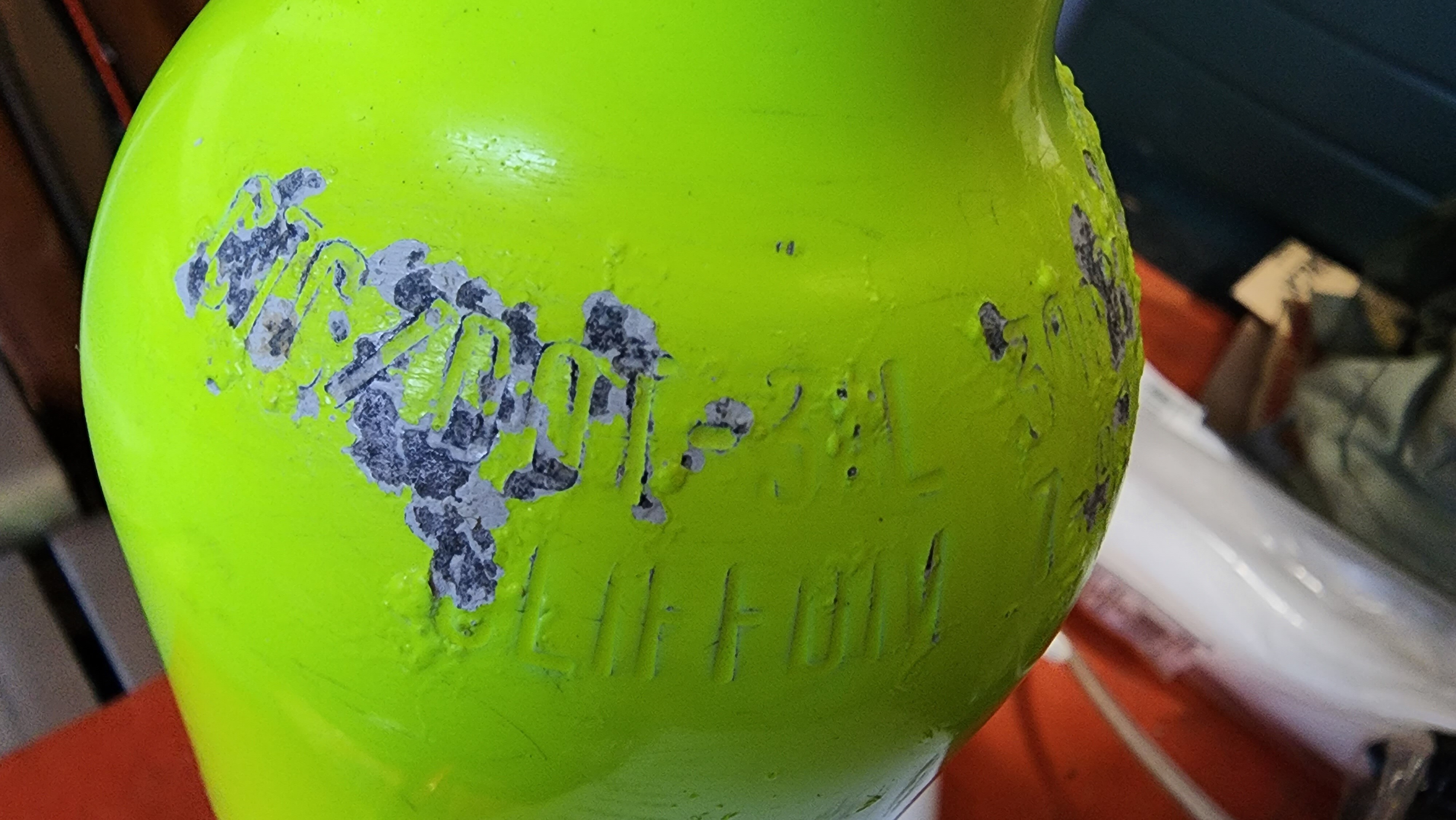

front and center is a pretty clear picture of a ruptured AA-6351 tank. Look closely at that picture. That picture showcases a classic "brittle fracture" failure mode..... Hmmmm..... brittle fracture? Just my opinion, but that speaks to a bad heat treatment process on that particular tank. Is there a lot or two of 6351 tanks floating around with a bad heat treatment ?? Inquisitive minds wonder.