H2Andy:

it does happen, especially with rental tanks (they get a lot of wear and tear)

And I think that's the thing about yokes. I've had my share of o-ring failures, all pre-dive, and all with yokes and rental tanks. The o-rings are on the valves, and (like H2Andy says) they can get a lot of abuse or just neglect if they're rental tanks. Plus, yoke o-rings tend to be a lot more exposed to damage (and abuse) on the valve.

With a DIN, the o-ring is on the first stage, which I think tends to be generally taken care of better than a tank valve -- if only because more people own their own regulators than tanks. We always cap them and take care of them. And, at least in North America, owners of DIN equipment are

on the average more experienced and/or may be more conscientious.

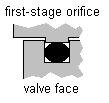

I'm not a technical expert, and I know I'm gonna get flamed... but I really don't think there's anything mechanically inferior with a yoke vs. a DIN, as far as the o-ring. People keep saying that DINs are superior because the DIN o-ring is "captured." But I don't buy that. I think a yoke o-ring, in good shape, that's not already damaged or extruded, in a fitting that mates correctly, is just as reliable; it's "captured" just fine by the flange on the first stage orifice. Maybe better. (See my pitiful attempt at a diagram, attached. Somebody correct me if I'm wrong... if I don't understand the definition of "captured o-ring"? Or how a yoke fitting seals?)

A yoke just can't take as high a pressure as DIN; but it's not because of the o-ring design. It's because at extremely high pressures, the two yoke arms tend to straighten and break the seal. But at 3,000 psi, the margin of safety with a yoke is pretty high.

We dive with DINs, but that's because of where we live.

--Marek