There is an interesting article in the Spring 2017 issue of Alert Diver Magazine: A Free-Flowing Failure

The plastic housing of the second stage failed and caused a freeflow. It isn't clear to me if the plastic housing was exposed to full IP pressure or not. Does anyone know what regulator this is?

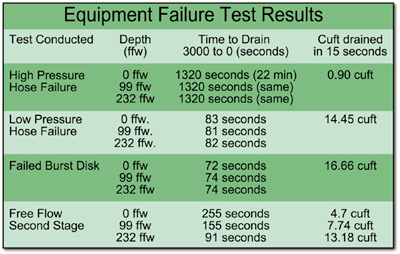

Here is a related article that shows how long it takes for various failures to empty a single 80 that appeared in Advanced Diver Magazine:

Life Ending Seconds, 3000 to Zero in 72 Seconds

The plastic housing of the second stage failed and caused a freeflow. It isn't clear to me if the plastic housing was exposed to full IP pressure or not. Does anyone know what regulator this is?

Here is a related article that shows how long it takes for various failures to empty a single 80 that appeared in Advanced Diver Magazine:

Life Ending Seconds, 3000 to Zero in 72 Seconds