also:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Servicing your own regulators

- Thread starter Rick Warren

- Start date

-

- Tags

- self maintenance

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

150 is 5 psi above the "allowable range". Are you confident of the gauge accuracy of what you are using?

The service kit contains 3 conical seats of different height. Choose the taller one , this reduces the IP...

Thanks for reply. cannot see all of the page printing.

1) what should IP be? or what is acceptable range?

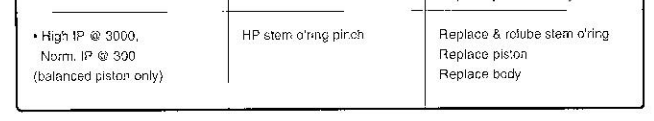

2) do main springs get stiffer if old and where do i get a new main spring if available.? Main HP seat brand new, Used a piston bullet so dynamic o-ring should be fine. what is this HP slom? o ring pinch?

I haven't yet cycled it many times yet.

Thanks for your help. mk

IP gauge is brand new. I don't know what is a conical seat. Nothing like that to my knowledge in the package.

1) what should IP be? or what is acceptable range?

2) do main springs get stiffer if old and where do i get a new main spring if available.? Main HP seat brand new, Used a piston bullet so dynamic o-ring should be fine. what is this HP slom? o ring pinch?

I haven't yet cycled it many times yet.

Thanks for your help. mk

IP gauge is brand new. I don't know what is a conical seat. Nothing like that to my knowledge in the package.

1) what should IP be? or what is acceptable range? 125-145 psi

2) do main springs get stiffer if old and where do i get a new main spring if available.? No longer available Main HP seat brand new, Used a piston bullet so dynamic o-ring should be fine. what is this HP slom? o ring pinch? HP Stem O-Ring Pinch

I haven't yet cycled it many times yet. Then do so....

Thanks for your help. mk

In the old style service kits they used to make available 3 different height seats (they have a conical cavity) to resolve issues... You might try shimming the seat, but it will be a really precision effort that likely will not be obtainable...I don't know what is a conical seat. Nothing like that to my knowledge in the package.

First and foremost make sure the piston knife edge is perfect.

See this thread:

How to Restore a Knife Edge Piston

Next, if there are no shims there are a few easy ways to lower IP a few PSI:

Use a PTFE grease on the piston stem, stem o-ring, and piston head o-ring.

Replace the seat (as per @Angelo Farina ) with a taller one. In the MK5/6/7/8/9/10 kits there are three seats. The tallest one gives the lowest IP:

Do not mirror polish the piston stem where it interfaces with the stem seal. Instead, break the shine with 600 grit or finer emery cloth.

If still no joy, try a polyurethane duro 90 -010 for the piston stem seal. Not my favorite, as they are expensive and have a short shelf life.

A radical approach, that only someone with a death wish would do, would shave the spring down just a little on a belt sander.

See this thread:

How to Restore a Knife Edge Piston

Next, if there are no shims there are a few easy ways to lower IP a few PSI:

Use a PTFE grease on the piston stem, stem o-ring, and piston head o-ring.

Replace the seat (as per @Angelo Farina ) with a taller one. In the MK5/6/7/8/9/10 kits there are three seats. The tallest one gives the lowest IP:

Do not mirror polish the piston stem where it interfaces with the stem seal. Instead, break the shine with 600 grit or finer emery cloth.

If still no joy, try a polyurethane duro 90 -010 for the piston stem seal. Not my favorite, as they are expensive and have a short shelf life.

A radical approach, that only someone with a death wish would do, would shave the spring down just a little on a belt sander.

Yes, please keep us updated (unless I gave you any bad information.)Thanks for the ideas. I woll work on it and respond back if anyone interested. Thanks again. mk

Thank you all for your advice.

I discovered the o ring at top of HP seat holder had extruded into the area of piston and was interfering with proper function . the o ring pinch. Once i got it seated properly, I had a steady IP of 130.

Again , thank you for assistance of all who helped me on scubaboard. mk

I discovered the o ring at top of HP seat holder had extruded into the area of piston and was interfering with proper function . the o ring pinch. Once i got it seated properly, I had a steady IP of 130.

Again , thank you for assistance of all who helped me on scubaboard. mk

Similar threads

- Replies

- 28

- Views

- 1,856