I am having a damn near heart attack every time an auto drain valve opens and 4000psi shoots with a excruciatingly loud pop and fizzzzzzzz.

I've tried a few things, - Even blew up a simple green bottle that had holes drilled into it and filled with rags.. My wife even came downstairs to make sure I still had all my limbs attached

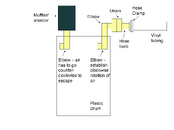

any ideas on economical silencing techniques?

currently have a towel tightly wrapped and duck taped which works, but very ugly and its starting to smell..

I've tried a few things, - Even blew up a simple green bottle that had holes drilled into it and filled with rags.. My wife even came downstairs to make sure I still had all my limbs attached

any ideas on economical silencing techniques?

currently have a towel tightly wrapped and duck taped which works, but very ugly and its starting to smell..