cocoajoe

Contributor

I have an Atomic Z2 reg with Atomic SS1 second purchased new about 4-1/2 years ago. Reg has always been good with no problems. SS1, not so much.

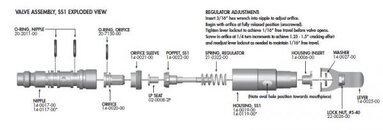

Towards the end of 2nd year, SS1 free flowed....fortunately I was at a shallow depth. Didn't freak me out too bad as I was close to the 2 year semi-annual service. Got it serviced and no problems. Fast forward 2 more years and serviced again. 1st dive after service, SS1 free flow while assembling gear....couldn't get it to stop. Blew the dive and whole day (dive was at BHB where you have a 1 hour window) Had shop to adjust it....watched what the tech did, did some research and added a 3/16" allen wrench to save-a dive kit....just in case it happened again.

After I got back home, I asked shop (where I had service done) what happened? Guy replied, sometimes something or other doesn't seat and it should be OK now.

A couple of dives later...SS1 free flowed (this time on a boat wreck dive no less... while setting up gear). broke out allen wrench and fixed problem.

Everytime this has happened, I've been either shallow, on a boat or dry land. I really don't want to deal with this at 80 or 100 ft

What gives?

Towards the end of 2nd year, SS1 free flowed....fortunately I was at a shallow depth. Didn't freak me out too bad as I was close to the 2 year semi-annual service. Got it serviced and no problems. Fast forward 2 more years and serviced again. 1st dive after service, SS1 free flow while assembling gear....couldn't get it to stop. Blew the dive and whole day (dive was at BHB where you have a 1 hour window) Had shop to adjust it....watched what the tech did, did some research and added a 3/16" allen wrench to save-a dive kit....just in case it happened again.

After I got back home, I asked shop (where I had service done) what happened? Guy replied, sometimes something or other doesn't seat and it should be OK now.

A couple of dives later...SS1 free flowed (this time on a boat wreck dive no less... while setting up gear). broke out allen wrench and fixed problem.

Everytime this has happened, I've been either shallow, on a boat or dry land. I really don't want to deal with this at 80 or 100 ft

What gives?