elmer fudd

Contributor

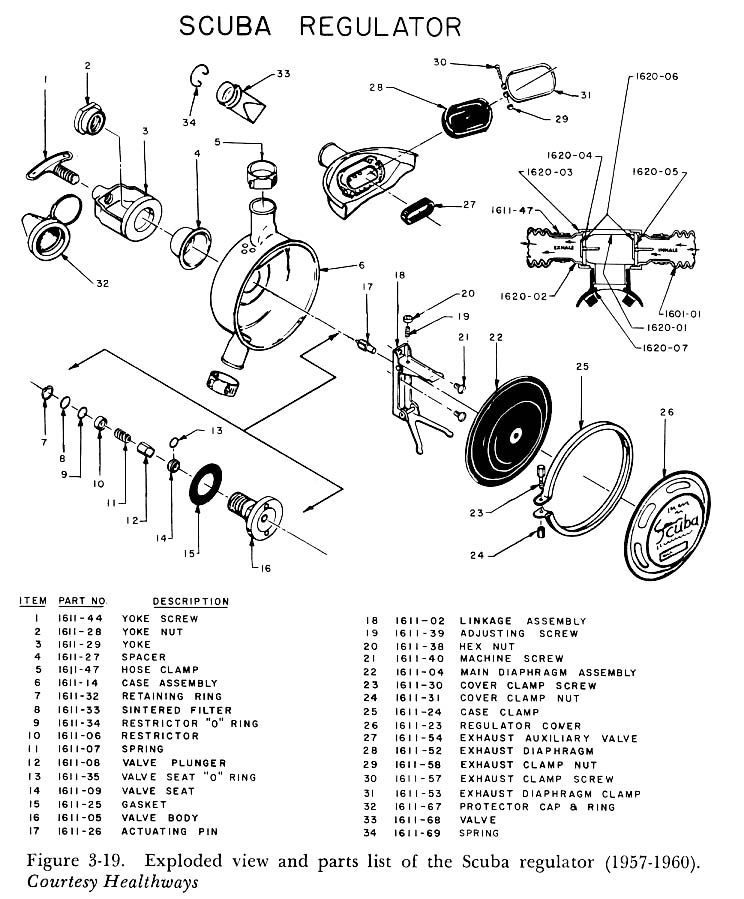

I'm pretty sure the exhaust valve was a rotten design. HW's themselves dumped it pretty quickly and nobody else ever picked it up. The problem is, where do you fit a working diaphragm in that tiny exhaust chamber? Also, the fact that the exhaust tube is part of the can really limits what you can do.

I got my silicone sheeting from Granger. There's one a few miles from me. They're not really in the business of dealing with the general public, (mainly commercial accounts), but the guy behind the counter was pretty good about letting it slide. It cost me something like $10 for 1 square foot of sheeting.

I got my silicone sheeting from Granger. There's one a few miles from me. They're not really in the business of dealing with the general public, (mainly commercial accounts), but the guy behind the counter was pretty good about letting it slide. It cost me something like $10 for 1 square foot of sheeting.