Has anyone left Nylon webbing bands on cylinders for long periods like years? If so, was corrosion and salt build-up under them any better or worse than under stainless bands?

I am making up a few sets of custom doubles bands and started thinking about alternatives to stainless. Underwater Kinetics used to make self-draining rubber-like cushion inserts that went under stainless bands back in the 80s, but I never left any on long enough to see if they actually did any good. It seems like Nylon webbing would dry better, but salt build-up might be worse. Either one as just as easy for me to make.

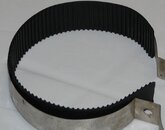

I dont think stretching will be a significant issue. I am thinking of using 2 Nylon webbing that is sewn into a circle with an overlapping seam. Two holes would be punched and melted, then backed by stainless plates/rectangular washers.

All ideas are welcome, I am an experimenting kind'a guy.

I am making up a few sets of custom doubles bands and started thinking about alternatives to stainless. Underwater Kinetics used to make self-draining rubber-like cushion inserts that went under stainless bands back in the 80s, but I never left any on long enough to see if they actually did any good. It seems like Nylon webbing would dry better, but salt build-up might be worse. Either one as just as easy for me to make.

I dont think stretching will be a significant issue. I am thinking of using 2 Nylon webbing that is sewn into a circle with an overlapping seam. Two holes would be punched and melted, then backed by stainless plates/rectangular washers.

All ideas are welcome, I am an experimenting kind'a guy.