I bought a complete fill station a few years ago. I had to do some reorganizing of the garage, so the assembly of the fill station fell on the back burner. I am now trying to get it back together.

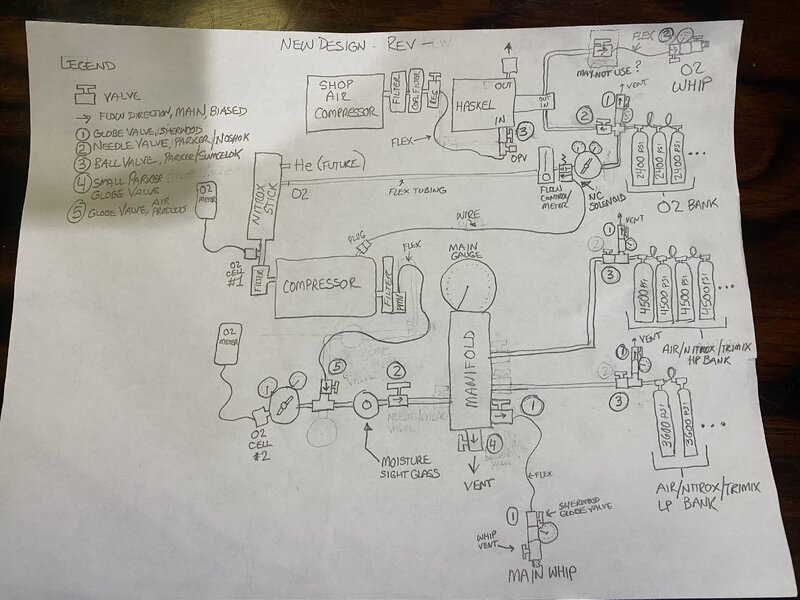

From my notes and pictures, and help from the previous owner, I was able to reconstruct the system on paper. After looking at it, I wanted to simplify it. Thanks Wookie for the help and pointers along the way.

Here are the main components used:

Let me know what you think.

Thanks for looking.

From my notes and pictures, and help from the previous owner, I was able to reconstruct the system on paper. After looking at it, I wanted to simplify it. Thanks Wookie for the help and pointers along the way.

- I wanted to reduce or remove the use of Quick Disconnects.

- I wanted to reduce the amount of tubing and fittings exposed to O2.

- I want to reduce the amount of flex hoses used.

- I wanted to use a shop air compressor rather than using banked gas to drive the Haskel.

Here are the main components used:

- Bauer Capitano ~5cfm

- Four 4500 psi storage bottles

- Two 3600 psi storage bottles

- Three 2400 psi O2 bottles

- Haskel AG30

Let me know what you think.

Thanks for looking.