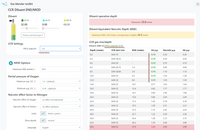

I've been using this software for a few weeks and often got wrong results. Today I realised the reason: ideal gas instead of real gas vDW. I think I choose factory setting which brings ideal gas (back).

I do not understand why real gas is an option anyway. If software is able to calculate real life (vDW) why should it calculate ideal gas as well? Ideal gas is always wrong, sometimes more, sometimes less but always wrong.

OK, for any reason you keep the ideal gas calculation. But please set real gas as factory setting, this is very helpfull.

Apart from this: great software, very easy to handle, very intuitive on PC as well as on smart phone. I like it very much. From now on I will calculate real gas and expect better results.

I wonder: you use 21.00/79.00 as air. As far as I know air is 20.9/79.1 (N2 including all the other gases).

Google sais air contains 20.942% of oxygen, I don't know if this is correct.

Why do you use 21.00% if you have 2 decimal places anyway? I know this does not change very much in result and I know I can choose my own gas for ex. 20.94/79.06. But why don't you do so? Air 21% looks non precise, non professional. 20.94 looks very precise, gives me the impression of a perfect software. Just an idea.

But still the software is great, thank you very much.

, but the most simple variant could be a non contact thermometer, for example like this one:

, but the most simple variant could be a non contact thermometer, for example like this one: