@rhwestfall has more G250s than he can count, he'll need more nuts than he can count...and I don't mean the denizens of Scuba Board.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SP G250 jam nut

- Thread starter Couv

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Let me get the cost for the G250, and I’ll start another thread to place ordering for the two G250, G250V.

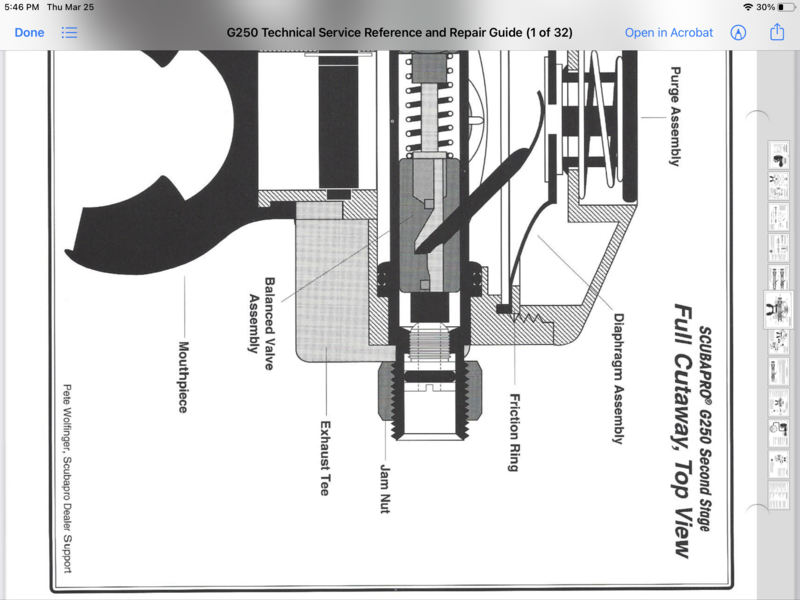

The OD on the G250 nut .743” is this Max it can be? Unfortunately I don’t have a G250 to measure.The nut in the picture from open water diver is the Halcyon nut. That nut will not work on a G250. The flared shoulder is too big. In my possession I have 4 G250V's, 3 G250's and 6 of the Halcyon nuts for the G250V's.

The OD of the flared shoulder on the Halcyon nut is .895"

The wrench flats on the Halcyon nuts is .667".

The Halcyon nut is .500" thick.

The points on the wrench flats are .743" (widest points).

The OD of the splined nut for the G250 is .743" and is .75" thick.

A typical nut with the 9/16 thread is .870 on the wrench flats, .992 at the points.

The Halcyon nuts will not screw down on to the G250 because the .895 flare is took large, it hits the exhaust tee.

If you flip the nut over, the nut will clear and tighten down correctly.

IMO, the nut needs to have wrench flats of .667", points of .743" and be .375" thick.

I am not sure why the base of the nut needs to be round (flare) and not a typical hex shape.

From this drawing maybe we can go larger.

1967Goat

Contributor

The largest feeler gauge I can slip between the nut and the exhaust tee is .018". So, you could go .036" larger (.018 each side of the nut). This leaves very little margin for error though. I would stick with .743", which leaves a few thousandths for a 3/4" (.750) wrench. My .02.

Couv..............4 please

rsingler..........10

1967Goat........8

Modi..............12

updated (I'd suggest we update this way)

Couv..............4 please

rsingler..........10

1967Goat........8

Modi..............12

rhwestfall........10

From this picture (courtesy of @buddhasummer ) we can see the flange cannot be much larger, if any, than the point to point distance of the hex nut.

@Modi in post #208 you pictured a prototype nut you machined. What would be the maximum diameter of the flange?

TIA,

Couv

@Modi in post #208 you pictured a prototype nut you machined. What would be the maximum diameter of the flange?

TIA,

Couv

@rhwestfall has more G250s than he can count, he'll need more nuts than he can count...and I don't mean the denizens of Scuba Board.

I have spent the last 3 weeks cleaning out the In-Laws house. They have been there since 1979.... Two 20 yard dumpsters have been completely filled, and we believe we will need another 12 or 20 yard to finish up.

I have begun to ponder liquidation of my "stuff".....

1967Goat

Contributor

I have spent the last 3 weeks cleaning out the In-Laws house. They have been there since 1979.... Two 20 yard dumpsters have been completely filled, and we believe we will need another 12 or 20 yard to finish up.

I have begun to ponder liquidation of my "stuff".....

That's completely different. Their stuff is "old junk", while your stuff is "spares".

That's completely different. Their stuff is "old junk", while your stuff is "spares".

You should see what I've kept...

generator, shop compressor and air tools, wire feed welder (left arc behind), torches, tools upon tools (power and hand - 4 chests & multiple cabinets), and on, and on and on..... Filled 1/2 of a car spot in my garage....

You should see what I've kept...

generator, shop compressor and air tools, wire feed welder (left arc behind), torches, tools upon tools (power and hand - 4 chests & multiple cabinets), and on, and on and on..... Filled 1/2 of a car spot in my garage....

Should fill a 10 cu yard dumpster quite nicely.

Similar threads

- Replies

- 1

- Views

- 534

- Replies

- 78

- Views

- 4,070

- Replies

- 152

- Views

- 9,547