- Messages

- 20,561

- Reaction score

- 14,946

- # of dives

- I'm a Fish!

@SurfLung do you have a manual for that starter? I think I found the one you used on amazon.

https://www.amazon.com/Big-Horn-188...N77PXKZ7XCX&psc=1&refRID=N6HZTVEQFN77PXKZ7XCX

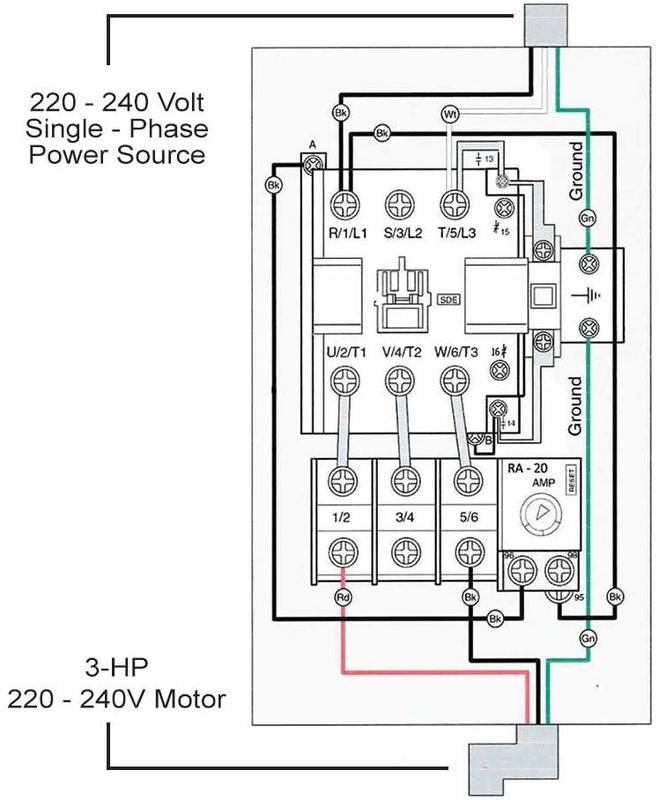

To get the pressure switch to work, you have to interrupt voltage to the coil itself. The key is making sure it's on a signal line, vs a power line, i..e nothing that carries any real current. It's going to have to interrupt one of the following lines. 96 to A, R/1 to 95, or the wire that goes to B. Without a better drawing or having one, I can't really tell you much else, but it's going to be in one of those wires which will open the circuit for the coil and drop the magnet back out. If you have a toggle switch laying around, I would start with that since it will do the same thing. Wire it between 96 and A first, start it up with the switch closed, and see what happens when you cut that circuit. It should function the same as the 20a breaker

https://www.amazon.com/Big-Horn-188...N77PXKZ7XCX&psc=1&refRID=N6HZTVEQFN77PXKZ7XCX

To get the pressure switch to work, you have to interrupt voltage to the coil itself. The key is making sure it's on a signal line, vs a power line, i..e nothing that carries any real current. It's going to have to interrupt one of the following lines. 96 to A, R/1 to 95, or the wire that goes to B. Without a better drawing or having one, I can't really tell you much else, but it's going to be in one of those wires which will open the circuit for the coil and drop the magnet back out. If you have a toggle switch laying around, I would start with that since it will do the same thing. Wire it between 96 and A first, start it up with the switch closed, and see what happens when you cut that circuit. It should function the same as the 20a breaker