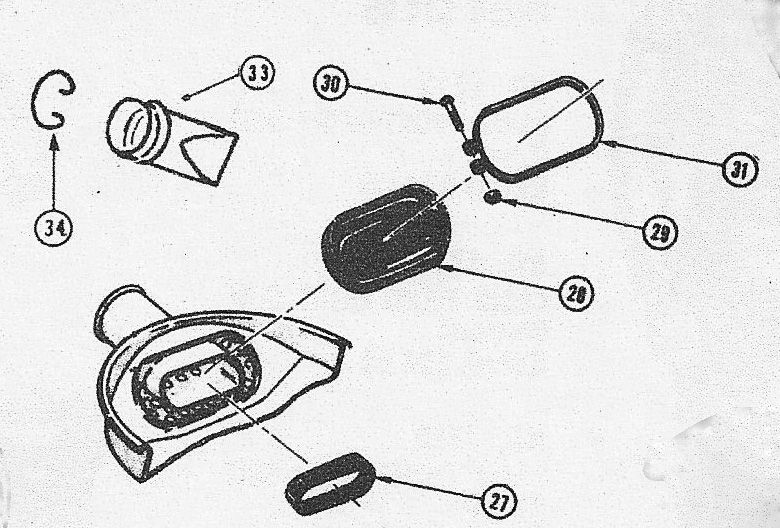

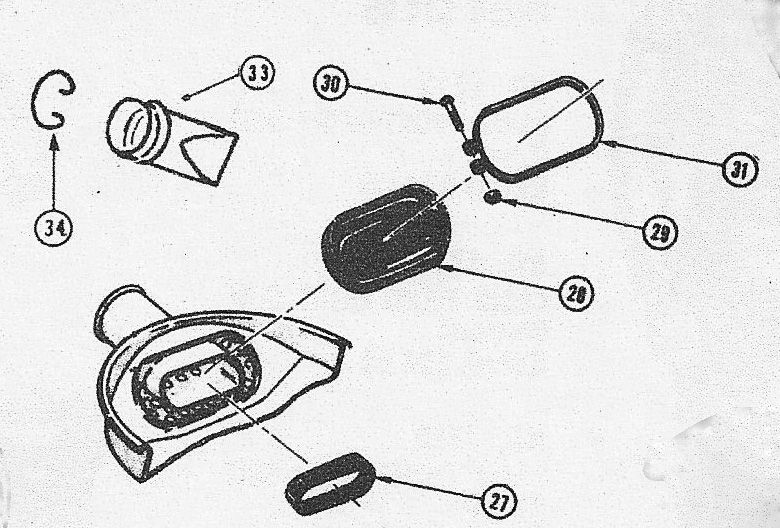

As for the exhaust diaphragm: This is a unique device that was used to circumvent USD duckbill patent. Basically it is an extension of the exhaust horn into the can. The extension is a rectangular tube cut at an angle that mirrors the rubber diaphragm you see inside the can with the wire "clamp". In theory, when air is being demanded, the pressure inside the can is greater than that in the exhaust hose and extension, thus this exhaust diaphragm is forced upon the extension and blocks it off. When exhalation occurs, the pressure of exhaling exceeds the pressure inside the can and the exhausted air pushes the diaphragm away from the end of the exhaust extension and escapes into the water via the holes. Healthways apparently had two modifications to this mechanism. The extension had holes in it that were covered by basically a rubber band. So that if the end was blocked too much by the exhaust diaphragm, air would exit via the holes that were covered by the rubber band. However another addition was made that was essentially a rubber impregnated "duckbill" that fit inside the exhaust extension. It was held in place with a internal spring clamp.

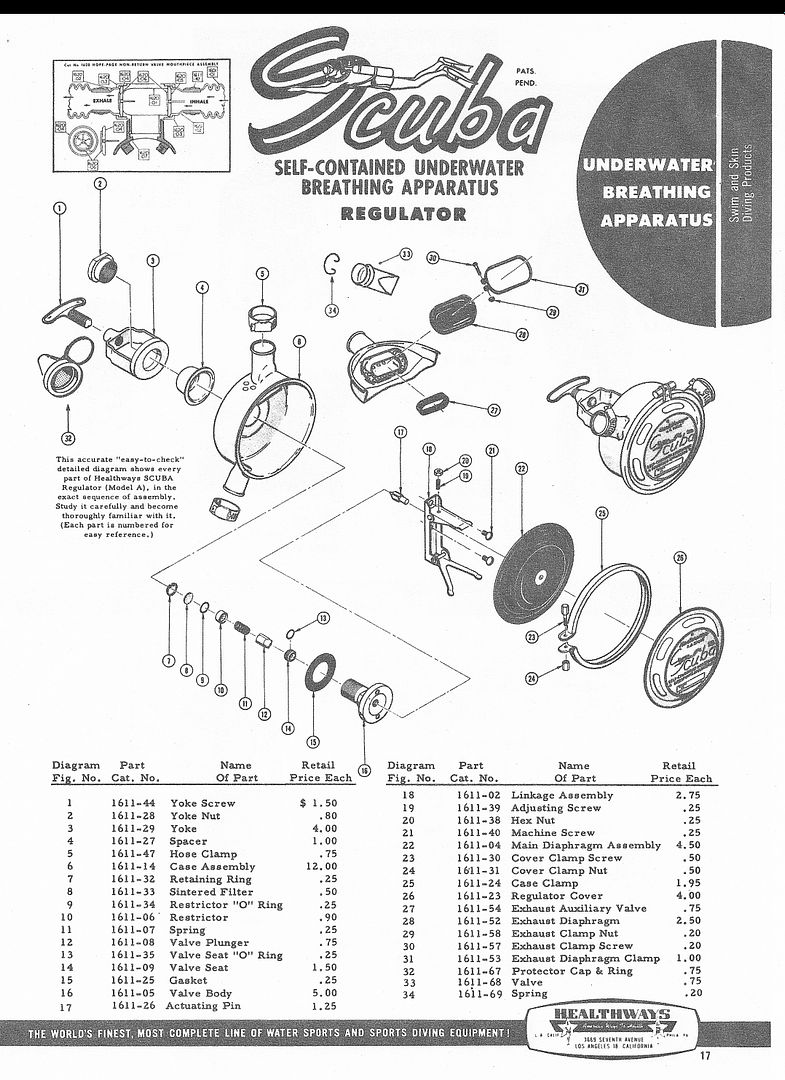

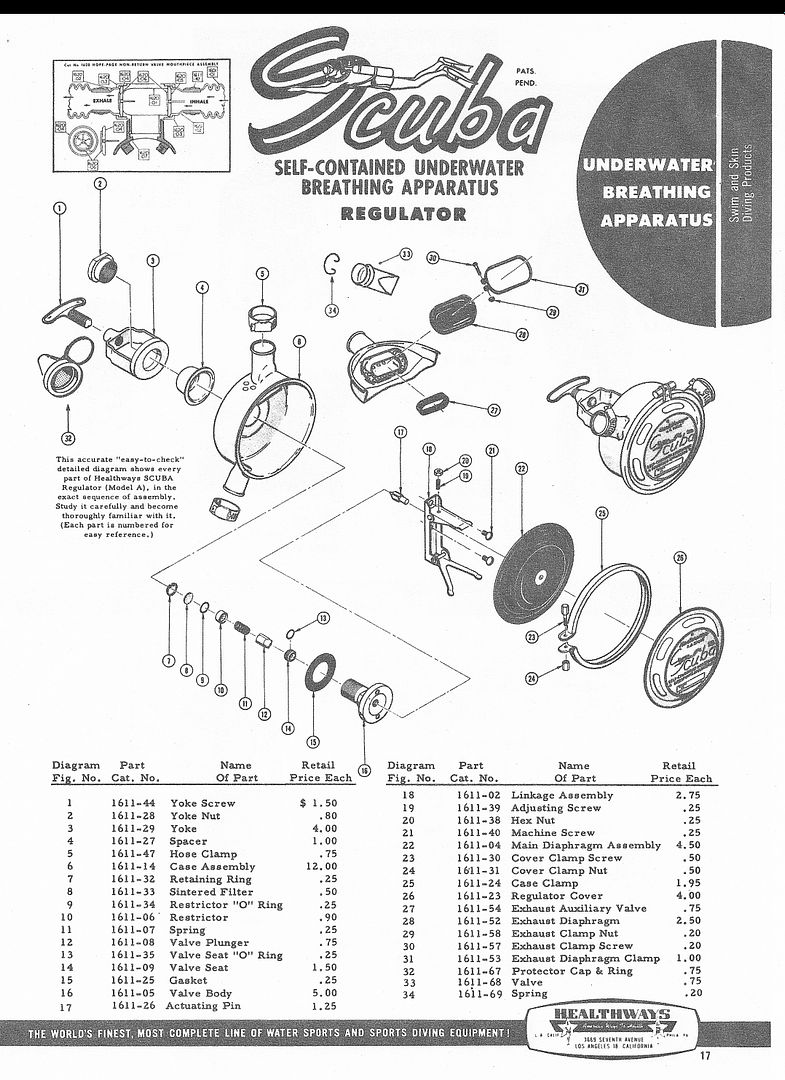

Simonbeans, I would like to apologize for putting on some Greek sentences. I started using the Greek in response to your earlier post. In the one I just pulled, I said that one of the reasons you didn't like some of what I said is that it is my experiences, and that sometimes it goes against the "mainstream" vintage community. For instance, this regulator that people say is difficult to work on has only seven moving parts. This particular one probably should be used only for the good parts. In the Greek that I put in, I said that you could be a bit overbearing. I tried today to reverse translate this part to see what it said, and couldn't get it translated, so I pulled it.

I use my experiences because I have done quite a bit of experimenting on this regulator, and my history with it goes back to 1959. This may appear narcissistic to you, but it is about the only way I know (I know, another "I") to communicate my findings on this regulator.

I have experimented on the exhaust, for instance by substituting sheet latex from a clean room glove for the exhaust diaphragm, and not having an internal duckbill. This actually produces very good exhalation characteristics, but when in a head-down position allows water to enter the exhaust hose. But in a normal swimming position it gives very good breathing characteristics for the exhalation phase. One other finding is that the use of this type of exhaust necessitates the use of an inhalation non-return in the mouthpiece, or the exhaust will be shut by the increased pressure exerted on the exhaust diaphragm by the exhalation. Here is a photo of the experiment with sheet latex:

And here are the parts:

One thing not too many people understand about this regulator is that having the lever arms at a 90 degree angle to the intake hose helps the breathing characteristics by providing a slight venturi going into the intake hose. This is because of the concave area near the lever arms in the valve body. The other thing that makes breathing better on this regulator is to have the lever arms adjusted as high as possible without leaking air. This takes a few minutes, and can be best done by holding the two parts (box and cover) together hard to simulate the effect of the clamp. Adjust it so that the arms are as high as possible and just leak, then back off the adjusting screw about 1/4 turn, put it back together then squeeze hard. If it doesn't leak, then tighten the lock nut and put it back together for one last test. If it doesn't leak, then you can put the parts back together, and the clamp on it. Breathing is actually pretty good. The venturi will never match the later model, or the Mistral, bit it is acceptable. [Now, that is one whole paragraph without an "I" except here.]

I appreciate your putting together the information on the exhaust system. [Another "I", if you're still counting.]

SeaRat