yes, you are correct

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

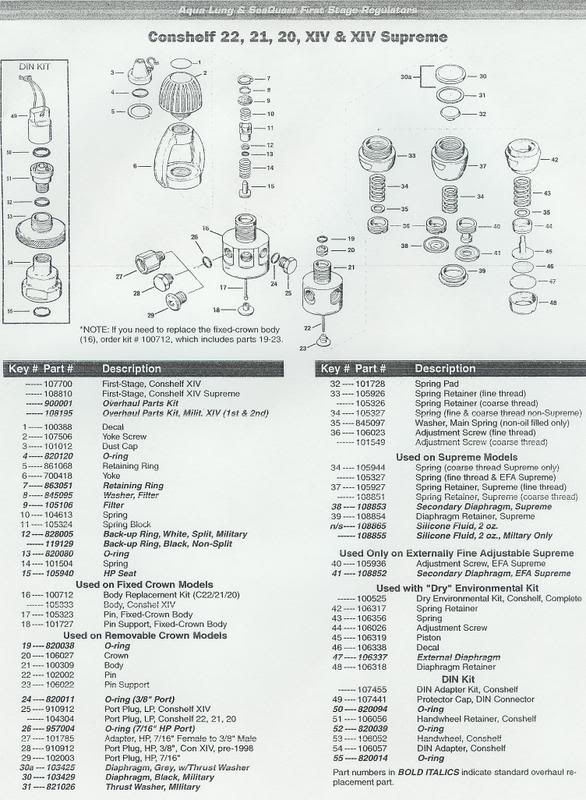

Volcano Orfice regrind On a conshelf

- Thread starter jbrians

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Brian,

Glad to hear it worked out for you. I've gotten a few off of the bay that had the o-ring and backup ring reversed. It's nice when you get a reg working well that someone tried to sell you as junk, is it not?

Glad to hear it worked out for you. I've gotten a few off of the bay that had the o-ring and backup ring reversed. It's nice when you get a reg working well that someone tried to sell you as junk, is it not?

Brian,

Glad to hear it worked out for you. I've gotten a few off of the bay that had the o-ring and backup ring reversed. It's nice when you get a reg working well that someone tried to sell you as junk, is it not?

I think the best way to elimate 20th century garbage/litter is to keep things working well for as long as possible before throwing them out.

Question on the Oring order. My manual doesn't actually say to put the nylon one in first. What's the difference in how it goes back together if you reverse them?

halocline

Contributor

The nylon split ring is there to keep the sealing o-ring in place without extruding. It must be on the downstream side of the o-ring to work, so that pressure pushes the o-ring into the nylon washer. Since outside of the balance chamber is the HP chamber, the pressure is pushing into the balance chamber, so you want the o-ring go in last.

If you put them in reversed, it might work for a while, but my guess is that the o-ring would wear much more quickly.

If you put them in reversed, it might work for a while, but my guess is that the o-ring would wear much more quickly.

Like Matt said, the purpose of the back-up ring is to keep the sealing O-ring from extruding. If the back-up ring is in the HP side is not doing anything, it might as well not be there.

When this first stage was first introduced (in 1964 & 1965) in the Royal Master and then the Royal Aqua Master, it did not have a back up ring. The back-up was added a few years later.

When the Conshelf was first introduced it was advertised and it capitalized on using the exact same well proven first stage as the Royal Aqua Master. I believe that the very first Conshelf did not have a back-up ring either (I am not positive about this), but it was added and retrofitted into all of them.

The back-up ring is not as critical with lower working pressures as it was the case in the mid 60's. With increasing tank pressures the back-up ring is increasingly important.

The back-up ring is also not needed if the gap between the mating parts is small enough that will not allow O-ring extrusion. In mass production parts keeping tight enough tolerance on moving mating parts to avoid the use of a back up ring is normally not practical. Due to manufacturing tolerances, the gap between the mating parts (spring block/ balancing chamber and the seat stem) is not always the same.

An O-ring will seal even if it is experiencing some minor extrusion. O-ring extrusion will reduce the life of the O-ring and will add drag and friction to the moving seat. Friction on the stem of the moving first stage seat can also cause fluctuations on the IP lock.

When this first stage was first introduced (in 1964 & 1965) in the Royal Master and then the Royal Aqua Master, it did not have a back up ring. The back-up was added a few years later.

When the Conshelf was first introduced it was advertised and it capitalized on using the exact same well proven first stage as the Royal Aqua Master. I believe that the very first Conshelf did not have a back-up ring either (I am not positive about this), but it was added and retrofitted into all of them.

The back-up ring is not as critical with lower working pressures as it was the case in the mid 60's. With increasing tank pressures the back-up ring is increasingly important.

The back-up ring is also not needed if the gap between the mating parts is small enough that will not allow O-ring extrusion. In mass production parts keeping tight enough tolerance on moving mating parts to avoid the use of a back up ring is normally not practical. Due to manufacturing tolerances, the gap between the mating parts (spring block/ balancing chamber and the seat stem) is not always the same.

An O-ring will seal even if it is experiencing some minor extrusion. O-ring extrusion will reduce the life of the O-ring and will add drag and friction to the moving seat. Friction on the stem of the moving first stage seat can also cause fluctuations on the IP lock.

Last edited:

captain

Contributor

My Conshelf VI and Swim Master MR 12 did not originally have the backup ring. The back up ring probably started around the time of the 3000 psi AL 80

The 3000 psi AL 80 was not introduced until 1972 (maybe 1973), IIRC, by then all the Royal Aqua Master and Conshelf have had the back up ring for a few years. I think it was introduced around 1968, maybe a bit earlier, but I am not sure about that. I didn't start repairing regulators until 1971, but by then they all had them. I don't know about Voit... you could only buy those in the one K-Mart in Caguas, Puerto Rico.

The back up ring is beneficial even for a 1800 psi tank, but it becomes increasingly important with 2250 psi , 2475 psi, and higher.

As I mentioned, how beneficial is the back-up ring can vary between any two regulators since the clearance between the mating parts is not identical on every regulator.

The need for a back-up ring is also affected by the durometer of the O-ring. The higher 90 durometer O-rings has less tendency for extrusion.

The back up ring is beneficial even for a 1800 psi tank, but it becomes increasingly important with 2250 psi , 2475 psi, and higher.

As I mentioned, how beneficial is the back-up ring can vary between any two regulators since the clearance between the mating parts is not identical on every regulator.

The need for a back-up ring is also affected by the durometer of the O-ring. The higher 90 durometer O-rings has less tendency for extrusion.

Last edited:

yes, you are correct

OK...so just to be perfectly clear.

This balance chamber is one with the lip on the inside making oring removal tricky.

When I put everything back together with the BC on the table with the hole up, the nylon ring goes in first (so it's at the bottom) and then the Oring goes in last.

Sorry to belabour this but I want to make sure everyone is using the same direction for up (;

OK...so just to be perfectly clear.

When I put everything back together with the BC on the table with the hole up, the nylon ring goes in first (so it's at the bottom) and then the Oring goes in last.

Correct.

Similar threads

- Replies

- 25

- Views

- 2,498

- Replies

- 3

- Views

- 1,004

- Replies

- 11

- Views

- 1,269