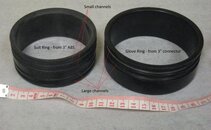

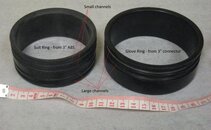

New Style! These work with installed latex seals

Needing a project (just like another hole in my head...) here is my latest dry glove ring system. This design works with the standard glued in latex wrist seals. It doesn't even stretch the latex seals very much. I have tested the system in my Jacuzzi using a second glove as the dry suit. I have not tested them in a real suit yet - as I no longer own a suit with suitable seals (ergo the jacket standing in as a dry suit in the photos).

The testing went well. With the single seal position it is possible to blow the glove off, but it takes some work. I doubt it would happen while normal diving. If it did in an overinflation state it might be a good thing. Even if you do blow a glove off the wrist seal still protects the integrity of the suit proper. In the double seal position you will rip something before the rings part OR it leaks.

Pictures first, then a blow by blow construction guide.

Parts needed:

1- 3-1/4" length of 3" ABS pipe

1- 3" slip-slip ABS pipe connector

4- #152 o-rings

8- #337 o-rings

1pr - heavy duty kitchen gloves without lining

Tools needed:

Lathe or drill press. I used a midi wood lathe, flat jaws, and a grooving tool I made from HSS steel from Harbor Freight ($4.99)

5 Piece M2 High Speed Steel Mini Tool Bits for Metalworking Lathes

All lathing was done using a standard tool rest and hand held. Finishing was to 600 grit.

Lathing can be done on a drill press or with a pen mandrel by making a wooden (or plastic) insert and lathing it to the inside dimensions of the pipe pieces. That was my original technique. Do ALL the work on an

end of a piece before removing it from your lathe - unless you are better than I am (quite possible) pieces don't install absolutely concentric and every time you re-install the piece you have to lathe it concentric again.

I like to work on the full 3" long pieces and after lathing the o-ring grooves then cut them in half to make the right and left rings. After lathing one end I flip the piece so I can work without hitting my knuckles.

Glove rings (the part the glove attaches to), makes a pair

1 - 3" slip-slip ABS connector. This slips

very tightly over 3" pipe

Lathe 2 grooves 6mm wide by 2.5mm deep near one end. Leave about 3-4 mm between grooves. Smooth well and finish to 600 grit. Flip the piece and do the other end. Cut the pieces apart removing the small inside ridge in the process. Round and sand the cut edge. I remount the rings and do this on the lathe, but precision isn't important here.

Cuff rings (the part on the dry suit sleeve)

1 - 3-1/4" length of 3" ABS pipe. Mark 1.5 inches from the ends. The remaining 1/4" is kerf space.

Lathe 2 grooves 6mm wide by 2.5mm deep near one end. Leave about 3-4 mm between grooves. Smooth well and finish to 600 grit.

Slightly decrease the pipe outer diameter of the ungrooved pipe until the Glove Ring slips on/off easily.

Lathe 2 grooves with centers 8mm apart. Each groove is 3mm wide by 1.5mm deep. Periodically install one of the #152 o-rings and try to slip the glove ring on. As soon as you can get it on, STOP. Sanding and polishing the groove will loosen the fit a bit. If you go too far you can start over, OR deepen it a little a put a rubber band inside as a spacer. When done the rings should fit together tightly but you should be able to remove them without any tools.

Flip the ring in the lathe and do the other side. Then cut them apart and dress the cut edges. Construction complete.

To install the cuff rings in your suit: Turn the sleeve inside out. Push the cuff ring with the smaller grooves facing the shoulder into the latex seal. Put a #337 o-ring over the inside-out latex seal onto the inside larger groove. Turn the sleeve right side out and put the second #337 o-ring over the outside of the latex seal into the outside groove (the one now closest to the shoulder).

Use the second pair of #337 o-rings to attach the gloves to the glove rings. Install the #152 o-rings in the smaller grooves and lubricate with soap, K-Y, or even silicon. The more lubrication, the easier it is to connect and disconnect the rings - use caution in the amount.

I will report when my Beta tester uses the gloves (2-4 weeks from now). Now off to work on some cuff rings to work with neoprene seals. For this my son is the Beta tester.