You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3d printed Sitech Antares dryglove cuff

- Thread starter mlavigne

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

@davidhicks - I cant do PETG or actual ABS, because i only have an SLA resin-type printer- great for tolerances, not great for flexible parts. I hadn't considered ribs or fins- i was concerned it would affect their ability to bend... but maybe if i just supported them at the bottom, it would be okay (change the spot it breaks at least). My ultimate goal is to find something better- i know this design if flawed, but i have a set, so i figured its easier to design something when i have a working one before designing something else from scratch.

@Badger7 - can you describe how the rolock bayonet portion seals? is there an Oring in there? I see how it seals to the wrist-ring (the ring sandwiches the wrist seal like sitech), and how the glove seals to the glove-ring (the glove seals via tacky rubber with silicone grease- also like the sitech seals with a backing ring for support), but what allows the glove ring to seal to the wrist ring?

There is a thin o-ring in the face of the cuff ring, when the glove ring is twisted in place it forms a seal by pressing against the o-ring. The solid connection of the design (twisting the two halves of the system together) resist any lateral forces that might separate the two halves and otherwise cause a leak.

Gloves do not seal with silicone grease. The smooth vinyl, nitrile, or latex material, depending on the glove being used, forms a seal between the retention ring inserted in the glove and the glove ring. The recommendation to add a very thin coat of silicone grease to the inner circumfrence of the glove ring is just to make it easier to press the retention ring and glove into place on the glove ring...it is not absolutely necessary but does help a bit...the grease is not employed to form a seal.

-Z

mlavigne

Registered

is the oring just loose when the glove is detached? it gets retained when the two faces mate?

looking here: Rolock dry glove system review and modification

last pic in post #13- i dont see any oring in there.

looks like DGX sells replacements, the part number 9703 doesn't mean much (not standard oring naming convention), but another site lists them as 70x3mm, which i can work with.

looking here: Rolock dry glove system review and modification

last pic in post #13- i dont see any oring in there.

looks like DGX sells replacements, the part number 9703 doesn't mean much (not standard oring naming convention), but another site lists them as 70x3mm, which i can work with.

is the oring just loose when the glove is detached? it gets retained when the two faces mate?

looking here: Rolock dry glove system review and modification

last pic in post #13- i dont see any oring in there.

looks like DGX sells replacements, the part number 9703 doesn't mean much (not standard oring naming convention), but another site lists them as 70x3mm, which i can work with.

The o-ring is retained in place by friction and the shape of the groove it sits in on the face of the cuff ring. Here is a picture taken by fellow SB member lexvil that shows the o-ring:

-Z

Because the face of the o-ring and the locking channel are (slightly) exposed when no glove is attached, I always though it might be a neat idea to print a dummy ring to cover both when not using dry gloves, maybe even for storage/transport. Can always pop the wrist ring and wrist seal out instead and replace it back with the stock oval ring I suppose for more than a few dives with out dry gloves. I looked around half heartedly for parts to see if i could find just the rolock90 glove rings as a separate item, and only found one seller and the price wasn't much cheaper than the whole rolock90 kit, which is why I may end up trying to print my own at some point.

Probably a solution looking for a problem, but that's the type of thing I think about when the snow is falling and I'm stuck inside.

Probably a solution looking for a problem, but that's the type of thing I think about when the snow is falling and I'm stuck inside.

Because the face of the o-ring and the locking channel are (slightly) exposed when no glove is attached, I always though it might be a neat idea to print a dummy ring to cover both when not using dry gloves, maybe even for storage/transport. Can always pop the wrist ring and wrist seal out instead and replace it back with the stock oval ring I suppose for more than a few dives with out dry gloves. I looked around half heartedly for parts to see if i could find just the rolock90 glove rings as a separate item, and only found one seller and the price wasn't much cheaper than the whole rolock90 kit, which is why I may end up trying to print my own at some point.

Probably a solution looking for a problem, but that's the type of thing I think about when the snow is falling and I'm stuck inside.

I like your idea and would be willing to purchase a set if you ever get around to making them. I would recommend designing them so they do not twist all the way that they touch the o-ring so that if used for storage purposes it does not leave the o-ring compressed for an extended period of time. Let me know how I can help move this endeavor to fruition.

-Z

elvenhome21

Registered

I've got 3d models for rolock 3, 90 and a custom 100mm version for big hands I'm working on

The "storage" ring could be designed with a groove that prevents any o-ring contact.I like your idea and would be willing to purchase a set if you ever get around to making them. I would recommend designing them so they do not twist all the way that they touch the o-ring so that if used for storage purposes it does not leave the o-ring compressed for an extended period of time. Let me know how I can help move this endeavor to fruition.

-Z

mlavigne

Registered

ahh, didnt even look at the exposed face, i assumed they were 'in' the bayonet part...

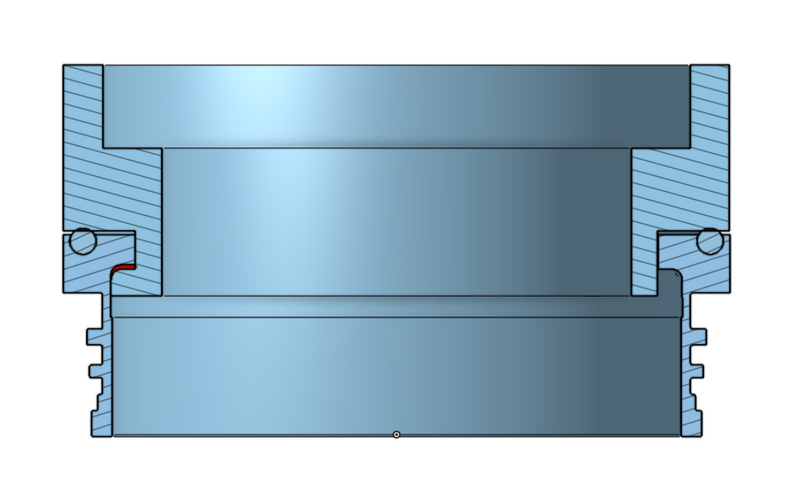

here's the rough sketch. I made 3 locking arms, so in the split-in-half section view, only the left side shows the lock (the other two are +/- 30deg out of plane).

I ended up using a 100mm OD oring (4mm diameter) that i found for cheap on amazon. Im not loving how small my hand hole is... 72mm/2.85"... i might have to open it up some more at the expense of strength... i guess the water pressure will be doing the sealing work for me so it doesnt have to be super strong.

I have a few more tweaks, then am going to print... should have a better idea of how it all fits together in the morning.

here's the rough sketch. I made 3 locking arms, so in the split-in-half section view, only the left side shows the lock (the other two are +/- 30deg out of plane).

I ended up using a 100mm OD oring (4mm diameter) that i found for cheap on amazon. Im not loving how small my hand hole is... 72mm/2.85"... i might have to open it up some more at the expense of strength... i guess the water pressure will be doing the sealing work for me so it doesnt have to be super strong.

I have a few more tweaks, then am going to print... should have a better idea of how it all fits together in the morning.

I just store with the gloves on, I give it about 1/4 of the travel and only remove the gloves after I’m ready to don the top half of the suit, it keeps the sand off of the mating surfaces.

Similar threads

- Replies

- 0

- Views

- 212

- Replies

- 0

- Views

- 260

- Replies

- 0

- Views

- 232

- Replies

- 21

- Views

- 1,619