I have had my KISS Spirit LTE CCR for over 8 years now, having bought two of them in 2015 for my wife and myself. This unit comes with a Hollis BOV with an integrated 2nd stage. It is a very simple unbalanced regulator. This BOV model has been used in a few CCR units from both KISS and Hollis over the years. I've not heard of one having a part disintegrate before, but it's happened to one of my units now.

View attachment 820200

Now back in September I broke my leg at the end of a 3-week safari trip, and another four months have passed healing up and not diving. I did my first dives in 147 days this last weekend! With the new year, and dive gear hardly touched in months, I did a full overhaul of the CCRs, checked the IP of all the regs, cleaned and lubricated all the o-rings I rarely remove, and rebuilt the BOVs. While doing this I noticed that the 2nd stage purge cover of the Hollis BOV 2nd was crumbling! Bits of plastic fell off when I removed it and it split in multiple spots. I put the unit back together anyway, and when I did a Pos/Neg test of the CCR it was leaking through the 2nd stage diaphragm. If I had tried to dive and breath off it, it probably would have breathed wet. I swapped in the BOV from the other KISS and broke my dry spell over the weekend. I then needed to fix the failed BOV.

The Purge Cover is a malleable flexible plastic like material, not silicone, but not fully rigid either. You can see below that it has a stem inside that pushes against the diaphragm when depressed and purges the regulator. Since it is flexible, it acts like a spring and bounces back. It also has a rim around the base, and this presses down on the perimeter of the silicone diaphragm to seal it against the regulator body. An outer ring screws down to seal the assembly of parts. But part of the rim has flaked off, so the seal is not complete. As a result, the Pos/Neg check is poor and it would probably breath wet.

View attachment 820201

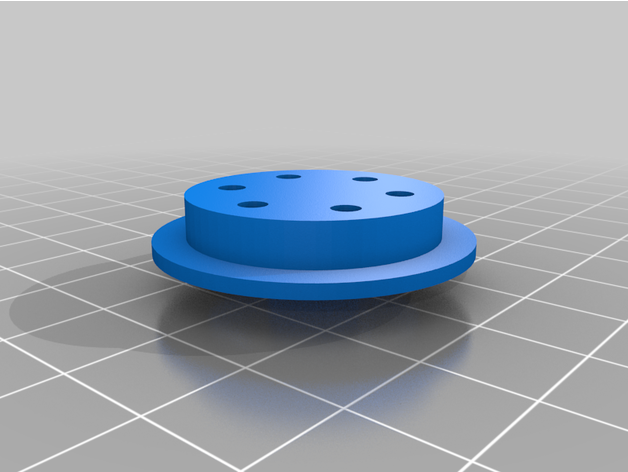

I started looking around for a source of replacements for this part of the Hollis 2nd stage purge cover. I don't know what model regulator this comes from, or if it was original to the Hollis BOV. KISS did not list it in their parts / spare catalog, and I could not find the parts on Ebay. I decided that I would attempt to 3d print a replacement before I contacted KISS or spent big buck on a new BOV.

I considered making a replacement purge spring cover with 100% soft TPU, but it can be a challenging material to print with sometimes, especially in a complex shape. The supports and overhangs can be messy. Instead, I decided on a 2-piece solution. I would make the body, rim, and raised portion with PETG, and then a soft springy center plunger/button with TPU. It took a few iterations, but I came up with something that seems to work pretty well.

View attachment 820204

Once installed in the BOV, the 2nd stage seems to work well, purging smoothly. The Pos/Neg test of the CCR is holding firmly now without the leakage of the loose diaphragm. All that is left is to dive it, which I will probably attempt tomorrow. I don't have much concern that it will work or not, but the longevity or reliability of the parts might be a concern. I've made a few other parts for my camera gear out of this identical PETG and TPU material that has stood up well to 100+ dives. I went ahead and made a second set of the parts to put in my spare kit in case there is any trouble. I'll keep a good inspection going as I move forward.

View attachment 820208

My final question to all of you; Am I nuts to dive this?

. Are the files in a Thingiverse current for the TPU diaphram cover? You liking them? I have 2 109s that are in need. Might be a good reason to get a new direct drive printer.